The user interface of the 'Single Blade' application has been improved and simplified. The proven method for the selection of the geometry and to automate the machining of impellers and blisks is now also available for blades.

New tool types

Improvements for reamers, barrel cutters in different designs and lens cutters will be demonstrated within the scope of tool support. Measuring probes are also supported. The quality assurance processes can be accelerated with the associated cycle 3D point measure.

Feedback from manufacturing

OPEN MIND provides a visualisation solution with the new hyperMILL® Shop Viewer, which allows the machine operator to check and simulate manufacturing processes directly via the monitor. The hyperMILL® Shop Viewer serves to display, analyse and document processed CAD/CAM data in a location that is close to the workshop. The traceability of the manufacturing process is noticeably improved via the toolpath simulation, the material removal simulation and the internal machine simulation. Possible errors can be recognised in time by virtual process analyses from experienced machine operators.

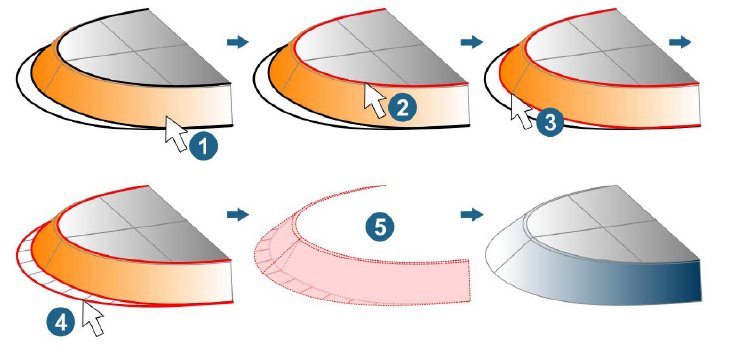

CAD deformations

hyperCAD®-S, the CAD program of the hyperMILL® suite, has been supplemented with the 'Deformation' module, with which targeted geometries can be deformed. This powerful modification tool allows the global or local modification of component areas, which is otherwise only possible with elaborate modelling techniques.