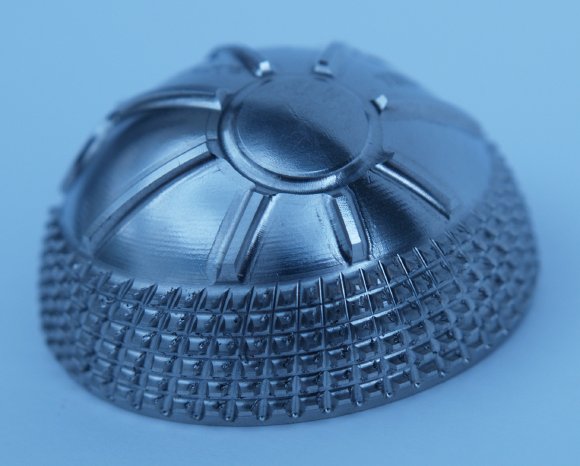

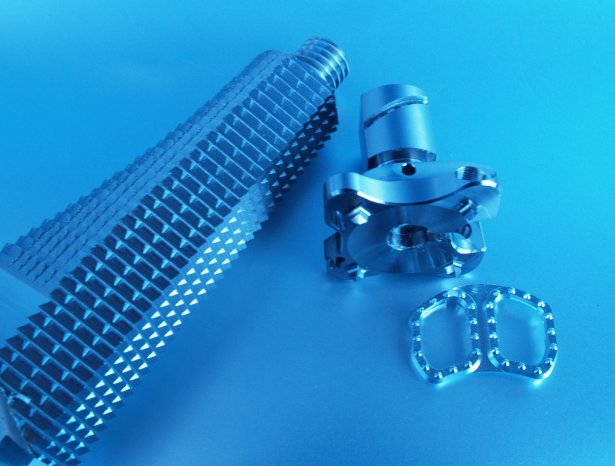

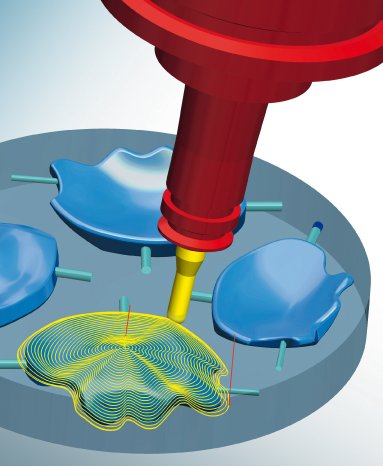

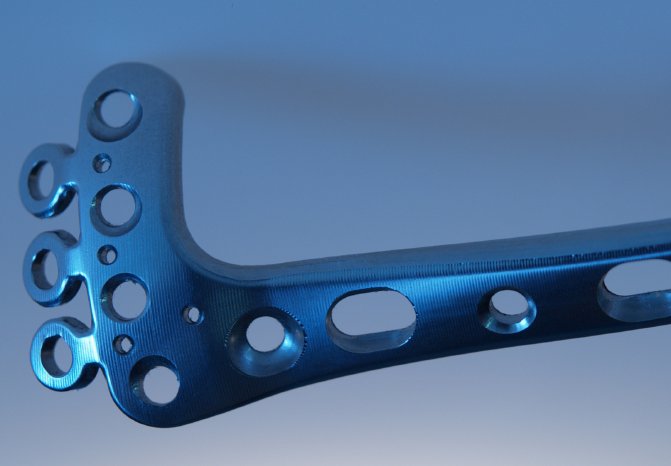

Companies benefit from the high manufacturing quality offered by hyperMILL®. Particularly with implants, optimal surface quality is crucial for ensuring compatibility in the human body. High-precision machining in medical applications using materials that are difficult to chip - such as titanium or hard metal - require optimal toolpaths and tool tilt angles. hyperMILL® offers a comprehensive concept for 5axis machining. Intelligent solutions, such as 5axis shape offset roughing and finishing, 5axis top milling or 5axis swarf cutting simplify the programming of demanding geometries, ensure high surface quality and reduce machine running times. The use of shorter and therefore more stable tools enables high-quality machining of high steep walls. Improved cutting conditions plus the reduced risk of chatter and tool breakage ensure the best results.

Faster programming

OPEN MIND relies on process automation and automated programming. The use of existing production expertise reduces programming times significantly. For example, hyperMILL® includes intelligent macros, which represent the next level in feature and macro technology. Thanks to intelligent macros, users can save predefined rules and conditions for every stage of the machining process. Job steps are automatically assigned and adjusted to the corresponding geometry in accordance with these rules and geometry information such as diameter, depth, open or closed pockets. hyperMILL® also demonstrates its time-saving potential in the programming of recurring geometries and identical elements. Transformation techniques facilitate the arrangement and copying of programs across the workspace. A mirroring function facilitates the programming of symmetrical parts.