At Stand D84 in Hall 6 and at Stand A152 in Hall 8, OPEN MIND Technologies AG will present hyperMILL® V9.7, which offers one of the most modern CAM programming environments for fast, flexible and cost-effective production. "These days, manufacturing companies have to be able to act quickly and flexibly if they want to be successful. On the one hand this requires intelligent CAM functions and automated functions that simplify, automate and speed up programming tasks. And, on the other hand, it's essential to have as broad a set of machining strategies as possible, preferably all made available within a single user interface", explains Ines Kaminzky, PR Manager at OPEN MIND. "The third important factor is process reliability, which, for example, collision control and avoidance, simulation and workspace monitoring all help to ensure." At EuroMold the company will demonstrate their comprehensive CAM concept in detail, including the innovative postprocessor technology and all its features.

Complete machining

The modern hyperMILL® CAM solution offers users a wide range of strategies for 2D, 3D, HSC, 5-axis and mill/turn machining accessed from a single, intuitive user interface. This comprehensive spectrum of machining strategies enables the creation of programs for complete machining in only one setup for both mill/turn machines as well as milling machines. At OPEN MIND's main stand (Stand D84 in Hall 6), visitors to the trade fair will be able to see how a wheel rim is milled on a 5-axis machining system from the company ALZMETALL.

Automated programming

Feature and macro technologies play an essential role in automated programming. hyperMILL®'s feature recognition technology allows geometric information that is generated in the CAD system to be used for CAM programming. Automatic feature recognition detects geometries such as holes, stepped holes with and without threads and open and closed pockets on solids and surface models. The parameters that are required for programming and for tool selection are generated during this process. Programming with features also enables changes to be made easily. Changes to the geometry or the technical parameters only require the feature to be modified. This data is automatically taken into account during recalculation. Machining strategies and tools can be linked with features in hyperMILL® using macros. These macros contain the machining rules for characteristic areas of the feature such as the thread diameter, the depth of the hole, the sink type or whether the pocket is open or closed. Once a macro has been created, it is stored in the clearly structured macro database. Comments and graphics stored together with the macro allow its contents to be easily understood by all users.

Reliable milling

OPEN MIND's postprocessors, which are tailored to machines, controllers and manufacturing processes, ensure that the CAM programs are processed seamlessly on the machine. Thanks to the new workspace monitoring users can specify a machine model and check in advance whether the machining job can be performed within the given workspace or whether limit switches will be traversed. The unique best-fit function automatically optimises the machining according to the available workspace and so facilitates optimal utilisation of space even when small or limited machines are used. Furthermore, thanks to the machine and removal simulation, collision checking can be performed right down to the smallest detail. The workpiece, tool and tool holder, clamping and machine movements can all be checked for potential collisions.

Continuous processes

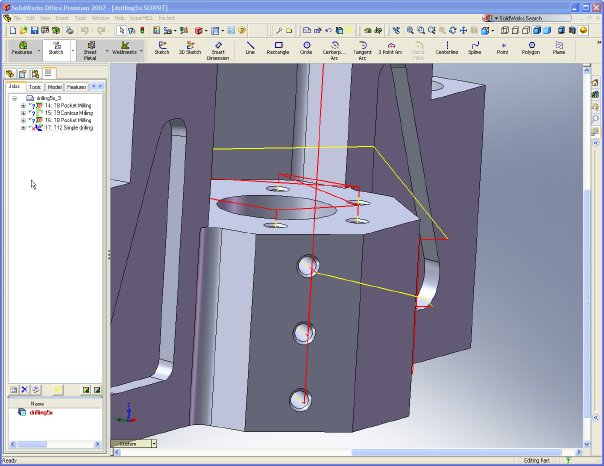

Version 9.7 of hyperMILL® supports the latest versions of leading CAD applications as an integrated CAM solution, including SolidWorks® and the current version of Autodesk® Inventor™ 2008 for the first time. hyperMILL® allows integrated process chains to be set up for the users of all current CAD solutions. A uniform data model is used for the entire process. This guarantees security and transparency throughout the production process and helps to eliminate errors.

OPEN MIND in the Mould + Die Centre, Hall 6, Stand D122

A highlight of this year's EuroMold will be the trade fair's first-ever Mould + Die Centre. In this centre selected companies will use highly automated tools and machines to demonstrate an entire production process for the whole value-added chain from the initial CAD construction of an injection mould to the finished injection-moulded part. This demonstration of the entire process chain from the CAD draft of the form using hyperCAD®, CAM programming using hyperMILL® all the way to production using precision tools from Emuge-Franken on a Huron machining system, provides visitors to EuroMold 2007 with a realistic example of modern production at the highest level of efficiency and process reliability.

Additional information is available upon request or from our website at www.openmind-tech.com.