In hyperCAD®-S, OPEN MIND has developed its own CAD system that is ideally matched to the CAM system hyperMILL®. This CAD solution is specifically designed to address the requirements of NC programmers. In Version 2013.2, hyperCAD®-S has been improved in a number of ways.

Importing and analysing parts

Tool and mould making, in particular, is always associated with geometries from a variety of sources. To import these reliably, hyperCAD®-S comes with a series of first-rate interfaces. They have now been enhanced for the import of 2D entities, 3D meshes and dimensions as vector graphics by adding a DXF/DWG interface. This allows for layers, colours, line types and workplanes to be imported, provided they were defined in the origin system.

If the parts are stored in hyperCAD®-S, they can be analysed thoroughly. Extensive functions are available to do this as well.

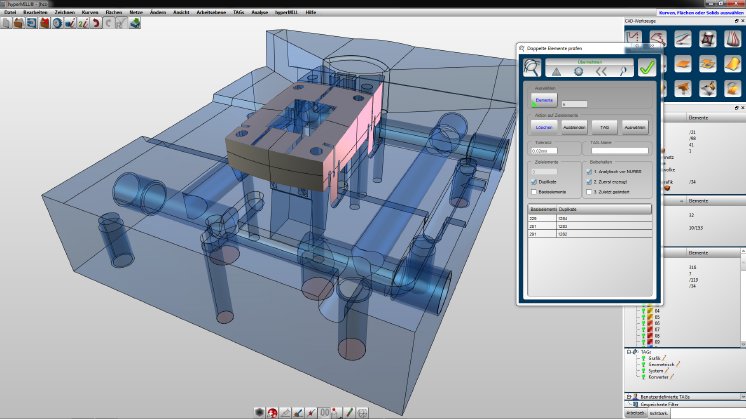

A new feature is the recognition of double entities. Regardless of whether this involves curves or faces, also within solids, as soon as they occur twice, they will be recognised and displayed. First, the component is displayed as transparent; the double parts found are then highlighted in the selection colour. This provides a quick overview: "The advantage of this new function is the reliable removal of double entities already in the CAD part of the system, which saves a lot of time during CAM programming," explains Wolfgang Weiss, product manager for hyperCAD®-S at OPEN MIND.

It is also helpful to now have the option to reverse a current selection. Through the inversion, the user can quickly isolate certain entities by, for example, selecting, inverting and rendering invisible other surrounding entities. What remains are the entities of interest. "It's a very important command, which makes the work substantially easier," says Weiss.

The analysis phase features the 'Info Two entities' command. When applied, the maximum distance between two entities selected is now also shown.

Editing parts

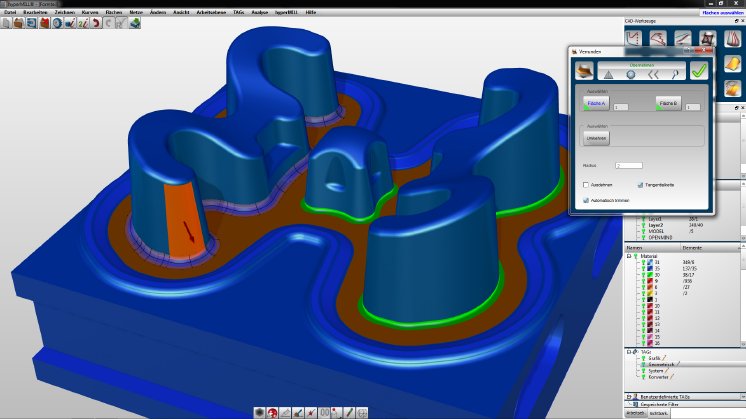

CAM users too must be able to make constructive changes to imported parts to some degree so as to prepare them optimally for NC machining. This often also includes the filleting of faces. Using hyperMILL® 2013.2, it is now possible to generate constant fillet faces between two faces or tangential chains that are trimmed and extended automatically.

Advanced edge curve recognition has also been added. This is a fully integrated function that substantially facilitates the user's work. The new command creates the topology of the faces, 'sews' them together and generates a clean edge boundary.

The command 'Integration of texts' is used to generate text along CAD entities such as lines, arcs and sectors. The text then appears on the part as engraving.

In order to access commands quickly at all times, there is now a list of the most recently used commands, which can be clicked on quickly from the workplane. The list comprises ten commands by default, but can be extended in any manner needed. It is the user who decides what is useful.

Finally, OPEN MIND has developed a new data format for hyperCAD®-S, 'hyperMILL® CAD Template' (hmct). This allows users to create, save and re-use templates in a meaningful manner.