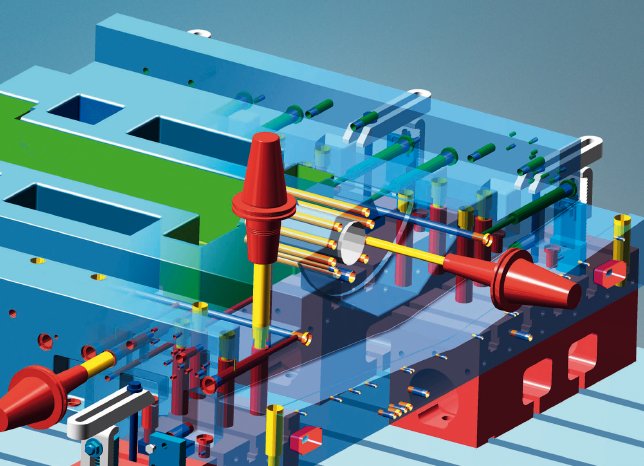

In CAM programming, a technology macro is understood as a specific sequence of machining steps with tool and technology data for characteristic geometries. In practice, macros enable 'programming with a click of the mouse'. For each geometry feature, the software independently searches for the right macro in a technology database in which all of the macros are stored. This enables the automatic creation of complete machining steps. The database is populated by saving machining processes (one step or more) that have been programmed with traditional direct techniques. No special programming skills are required to prepare the technology macro database.

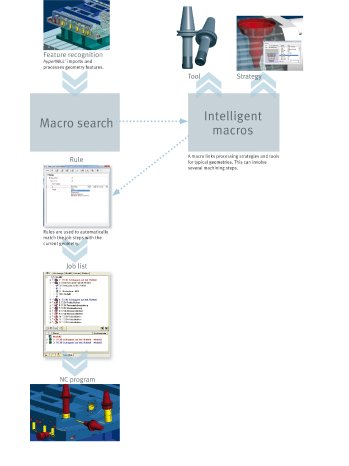

Intelligent macros

hyperMILL® can now store the various job steps required to fully process a part model. Rules and logical conditions can be defined for each individual job step. hyperMILL® automatically adjusts job steps on the basis of these rules and in reference to the geometry information.

For example: Let us take a hole with a diameter of 8 mm that may have various depths of 6 mm, 14 mm, 30 mm and 120 mm. Depending on how deep the hole is, different machining approaches are required. These can now be completely stored in one single macro. With a simple 'if-then rule', the relevant part of the macro is put into action.

When drilling, it had previously been sufficient to select a macro based on a reference number and checking the required tool length. Now, in hyperMILL® version 2013.2, the user can also run a search to find the hole diameter. For example, if a drill macro is applied to a hole with a diameter of 4, then the macro will look for a drilling tool 4 in the database. If the same macro is applied to a hole with a diameter of 6, a drilling tool 6 will be retrieved automatically. So, this is an automatic tool search, one that now also takes into account the hole diameter, meaning more convenience for the user.