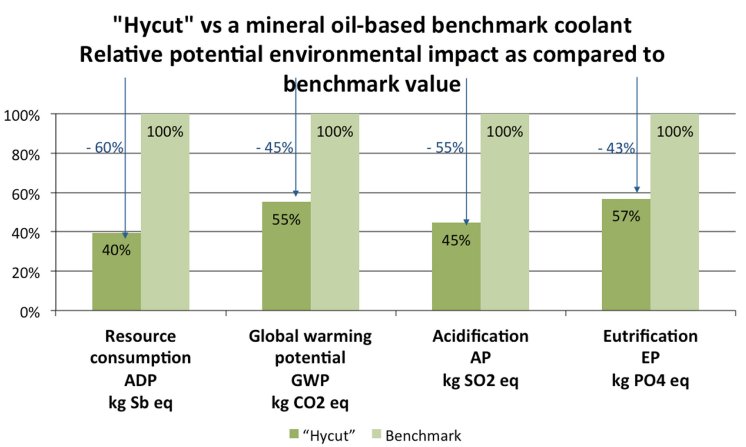

“We expected a good ecobalance, but both we and our customer were pleasantly surprised by just how positive the results were”, says Stefan Joksch, Technical Director at Oemeta. According to a study titled “Life Cycle Assessment of Metal Removal Fluid systems in metalworking applications – Evaluation of environmental impacts using the example of crankshaft manufacturing”, Oemeta’s HYCUT system can improve environmental values by up to 60%. The study was initiated by Oemeta, in collaboration with a German manufacturer of premium automobiles, and conducted by the Institute of Machine Tools and Production Technology at the Technical University of Braunschweig. It uses LCA to analyse the potential environmental impacts of mineral oil-free, multifunctional HYCUT oil, and compares these impacts to those of a conventional mineral oil-based lubricant system.

In order to comprehensively evaluate a product’s environmental impacts, the product’s entire life cycle – from raw material extraction through to manufacture, use, and disposal – is taken into account. The assessment measures both the consumed resources, and the emissions produced along the life cycle of the product. This occurs across all of the examined processes, such as production and disposal processes, energy generation, transportation etc., and converts these values into environmental impacts. The results are related to an indicator substance. For example, global warming potential (GWP) is related to the indicator substance CO2 and given in kg CO2 equivalents.

Carryover of metalworking fluids is not a problem

The investigation was carried out as part of a case study on the process chain in crankshaft production, which looked at a diverse range of machining methods, such as milling, turning, deep drilling and grinding. As the process chain frequently alternates between steps involving water-miscible and non-water-miscible cooling lubricants, washing processes are integrated between the steps.

Using ester-based, multifunctional HYCUT oil ensures that water-miscible and non-water-miscible components are compatible. This means that the introduction of metalworking fluids by means of adherence on components is no longer a concern. On the contrary: Oil that has been carried over is used as a lubrication performance in the emulsion during subsequent processing. Compared to mineral oil-based benchmark products, this results in a much more efficient use of cooling lubricants throughout the entire manufacturing line. Intermediate steps can be eliminated and metalworking fluid waste is practically non-existent. Reusing the washing agent, employed to clean the components, as a cooling lubricant during the manufacturing process also has a positive effect on the ecobalance. In summary, the use of the HYCUT system significantly reduced the environmental impacts (40-60%) in all of the categories examined throughout the entire life cycle.