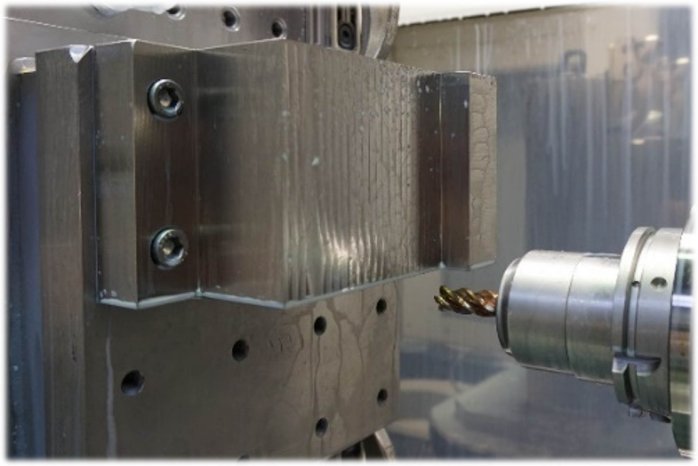

“It’s almost unbelievable that a new cooling lubricant can literally double tool life, but that’s what the independent measurements show,” assures Malte Krone, Head of Marketing & Product Management at Oemeta Chemische Werke GmbH. The new metalworking fluid ESTRAMET S 77 is made from synthetic ester oils and achieves outstanding lubricating performance, in particular for materials that present difficulties in machining, such as high-alloy steel, titanium and nickel alloys. This high lubricating performance reduces wear and preserves the cutting edges of tools. The Institute of Production Management, Technology and Machine Tools (PTW) in Darmstadt carried out machining tests and measured a 100 percent increase in tool life when slot milling Ti64 and Alloy 718. The manufacturer can thus promise its clients more components per tool and fewer tool changes.

Impressive machining results and surface quality

The new MWF is free of mineral oil and other lubricating substances such as sulfur or chlorine compounds. The combination of cutting-edge ester oils results in exceptional lubricating performance, making it possible to achieve ambitious cutting parameters. “For example, during thread forming on a lubrication test bench, the torque measurements were 40 percent lower than for mineral-oil-based products,” reports Krone.

When used with sharp tools, ESTRAMET S 77 ensures outstanding machining results with high-quality surface finishes, as it prevents chipped or built-up cutting edges. The emulsion is also a powerful cleanser, and its reduced oil content prevents contamination of components and machinery, which simplifies the cleaning process. “Even the swarf is cleaner and easier to recycle,” says Krone.

Economical and long-lasting

The new product can be used at concentrations of 3.5 percent and above, meaning much smaller quantities are required than for comparable high-performance cooling lubricants. According to the manufacturer, up to 50 percent less concentrate is needed for new filling and – much more importantly – refilling. The emulsion’s long service life also makes for longer change intervals and a reduction in machine downtime. “Users who keep an eye on total costs and calculate ahead can achieve significantly lower process costs using ESTRAMET S 77,” concludes Malte Krone confidently.