mycon GmbH is a sister company of the service company Kipp Umwelttechnik GmbH, active in the development, production and sale of new products and automation technologies. Many years of experience in the field of industrial cleaning and service led to several system developments and patents with some international validity.

The systems works fast, gently, with little waste and no production stoppage - this is how the use of the mycon products pays off in short period.

The rental service of mycon GmbH also offers the possibility to use the advantages of the mycon devices without high investment costs.

Also represented at the stand of mycon GmbH will be the two investment companies Puraclean GmbH (Switzerland) and the new investment company in France, which is being established, as well as Hubei Infinity Railway Technology Co., Ltd as a co-operation partner in China.

mycon GmbH will be presenting a large number of cleaning processes for railway technology at InnoTrans.

Cleaning of heat exchangers with JetMaster ensures the functionality of air conditioning / ventilation systems

JetMaster is the gentle cleaning system from mycon for intensive cleaning of sensitive fin surfaces of heat exchangers. JetMaster is also available in automated versions.

Depending on placement and environment heat exchangers, chillers and coolers can become contaminated very quickly. Industrial dust, calcification, pollen and other influences cause continuous deposits with negative effects on function and efficiency and, last but not least, on energy consumption.

The contamination of an air-cooled condenser or chiller forms an insulating layer, reducing energy efficiency and thereby increasing the cost of power, maintenance and service. In addition, the corrosion of the fins leads to a reduced operating time of devices.

Definitely for a sophisticated and material-friendly solution: JetMaster - the gentle but extremely intensive cleaning of heat exchangers by low pressure. JetMaster is the patented process of mycon GmbH for the intensive cleaning of sensitive lamella surfaces. JetMaster works gently and extremely powerful. High-performance nozzles brings compressed air and small quantities of water specially pretreated in the device at low pressure with supersonic speed. The gentle beam penetrates deeply into the devices without bending or damaging the fine fins. The contaminants are gently but effectively released from the surfaces by cavitation effect using discharged through the jet stream. Damage to the lamellar surfaces, as possible with the use of high pressure water cleaning, is completely eliminated if the JetMaster is used correctly.

Even sensitive surfaces such as soft coatings, graphite, glass, foils etc. can be thoroughly cleaned without damage.

JetMaster process gets support: SpeedMaster

The JetMaster system from mycon GmbH has been successfully used for years to clean lamellar heat exchangers and other sensitive surfaces, even in railway companies. Kipp Umwelttechnik GmbH, sister company of mycon, has now developed another process for the cleaning of even viscous grease layers: SpeedMaster. The SpeedMaster process works just as gently as the JetMaster system. SpeedMaster can be used to clean bogies in railway areas, to clean the inside of tanks, but also to clean pipes, bars and profiles. The cleaning agent can usually be completely reusable after treatment. The release of the new process for all applications is scheduled for September 2018. A prototype system for the automated cleaning of bogies and wheelsets in the railway sector is in the works and can already be offered for the trade fair.

PowerMaster - gentle, powerful and low-waste cleaning

PowerMaster is a blast system that works with compressed air, small amounts of water and water-soluble abrasives without damaging surfaces. mycon also offers PowerMaster as a complete automated cleaning system.

The proven cleaning method is based on an environmentally friendly and water-soluble granulate, which is introduced into a compressed air jet stream. Shortly before exiting the jet nozzle, the granules are wetted with water to increase the kinetic energy. The granules do not affect the function of a downstream separator.

PowerMaster cleans, peels and removes powerful and low-waste. The system works cost-effectively in the low pressure range between 3 and 8 bar compressed air with a low water consumption. Use of the abrasives recommended by mycon, even polished stainless steel surfaces or light metal surfaces can be cleaned or removal without visual impairment of the metal surfaces. Foils, paints, varnishes or resins, greases, bituminous layers or lubricants agents can be removed gently, quickly and economically with PowerMaster. Also for cleaning plastic surfaces PowerMaster can be used with a lower air pressure value. PowerMaster can be equipped for cleaning large areas with special nozzles up to 160mm wide.

When removing minor soiling, PowerMaster can also be used with a combination device in the area of painted Surfaces.

IceMaster - Modern industrial cleaning with dry ice

IceMaster - Effective, cost-effective, infinitely automatable

Dry ice or dry snow produced from liquid CO2 directly fed in the blasting gun with a stream of compressed air and blasted onto the surfaces to be cleaned at high speed. The process allows cost-effective and unlimited automated cleaning.

The IceMaster process is patent protected

Dry ice blasting has been used successfully for a long time in numerous industrial sectors for cleaning purposes. However, high operating costs, complex infrastructure and a lack of automation capability meant that the process did not get beyond a market niche despite its good performance.

IceMaster revolutionizes dry ice blasting for industrial cleaning. Low operating costs, full automation capability, constant availability without re-ordering of dry ice pellets are only a few of many advantages. mycon also offers IceMaster in automated versions according to customer requirements.

If required, mycon can also supply complete workplaces and complete automation systems with sound-insulated solutions for the manual use of IceMaster.

One mycon special solution is the cleaning of electronic components with IceMaster without electrostatic charging.

Application advantages:

- Minimized operating costs

- Low compressed air requirement: from 1.00 cbm air volume - min. / 1 bar

- No investment required, IceMaster is also available on a rental basis

- Constant availability

- Easy to use

- Full automation capability

- New: cleaning of electronic components, e.g. of controllers without electrostatic charge

- Cleaning surfaces made of plastic or metal

Cleaning of railway bogies for the purpose of weld inspection

Coating through thin-film surfaces

The cleaning of special plant parts can be significantly simplified and accelerated by the previous application of a hydrophobic protective layer. Even flexible parts such as insulators can be coated. Advantage: Experiments have shown that in subsequent cleanings with the JetMaster system, the coating is not damaged.

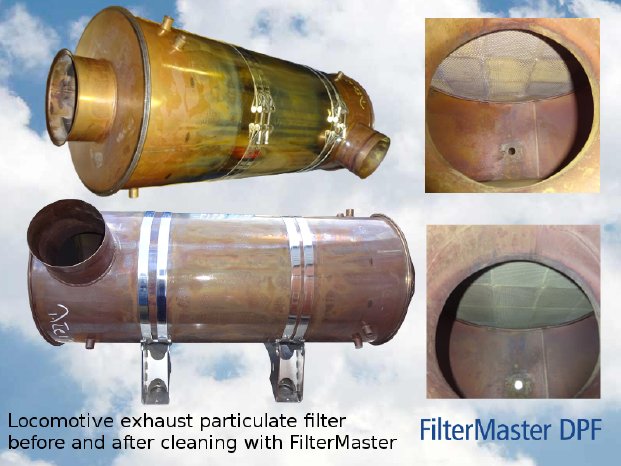

FilterMaster reliably cleans even large diesel particulate filters and catalysts without separating the housing

Successful cleaning of particle filters from locomotives, ships, buses, trucks and more are possible with the FilterMaster cleaning systems of the company mycon and have been executed many times.

The patented filter cleaning systems FilterMaster for trucks and more and FilterMaster for cars and more represent a new form compared to the previous concepts in the cleaning range for DPF. For the cleaning of particle filters and catalysts, the mycon systems represent a quantum leap over conventional methods.

FilterMaster for trucks and more

For filters that are openly accessible at the front, certain carbon dioxide-compressed air mixtures as well as some other industrial gases are used. Specially designed jet nozzles are used to clean the metal and ceramic filter surfaces.

Each type of filter can be precisely controlled and processed with exact repetitive accuracy. The system works in a closed circuit. Adaptive flange rings enable the almost every type of filter. Even angular filters of older design can be cleaned easily. Depending on the type of filter, the entire filter surface is automatically controlled and almost completely cleaned from the original soot and ash content.

FilterMaster for cars and more

The patented FilterMaster for cars and more cleaning system is used to clean exhaust particulate filters whose filter surfaces are not completely accessible through housings. For cleaning with this system, no separation of the filter housing is necessary. Even difficult-to-access filters of any size, even with upstream baffles or similar flow deflections can be easily cleaned with this cleaning system. Thus, a weakening of the housing by welds or corrosion resulting from welding can be excluded from the beginning.

On request, a fully automated mycon filter cleaning system is available to the customer for the particle filter cleaning with regular filter cleaning. Like all mycon machines, these cleaning stations are available on a rental basis without any investment costs including installation / commissioning on site.

About Kipp Umwelttechnik GmbH, www.kipp-umwelttechnik.de

In the field of industrial cleaning, Kipp Umwelttechnik GmbH is the specialist for thorough and gentle cleaning in industry and for building cleaning.

Kipp Umwelttechnik GmbH was founded in 1991 as a sister company to the construction company Jens W. Kipp Tiefbau GmbH, which has existed since 1971. Both companies are businesses managed by entrepreneurs.

mycon GmbH has added to the group made up of Kipp Umwelttechnik GmbH and Jens W. Kipp Tiefbau GmbH since 2002.