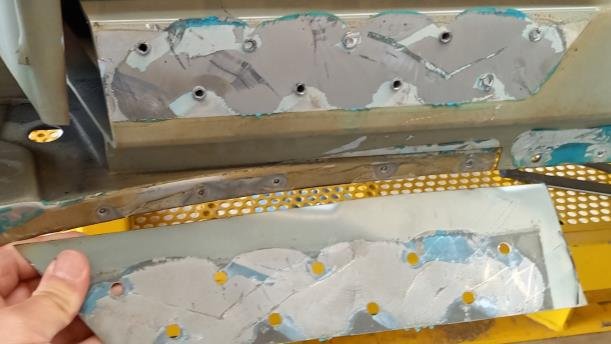

While cooling the surfaces down to -70° C, the adhesive layer was cooled down to -60° C. Thus, the adhesion became brittle and the autobody sheets could be loosened with the help of a special device.

Several experiments conducted by the LWF of Paderborn University and the University of HammLippstadt confirm that the adjoining adhesive bonds were not damaged by the use of SplitMaster after the application of SplitMaster. Likewise, the adjoining surfaces with anticorrosive coating stayed free of damage.