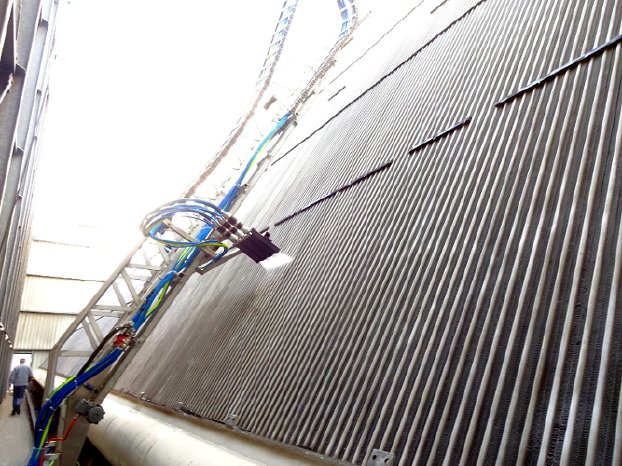

No employees are needed to conduct the fully-automated, patented JetMaster process. The system’s electronic controller offers multiple cleaning programs that can be selected easily at the push of a button.

Video - JetMaster AS works fully automated

The JetMaster AS is environmentally-friendly, with jet widths of 500mm, for instance, and a water usage of over 240 l per hour. Approx. 100m2 of the exchanger’s surface can be cleaned in just one hour. The system also produces only a small amount of waste water. The JetMaster AS is chemical-free, using only 5-7 bar compressed air and water. The JetMaster process delivers outstanding quality cleaning.

What applications are suited to using the JetMaster AS automated cleaning system?

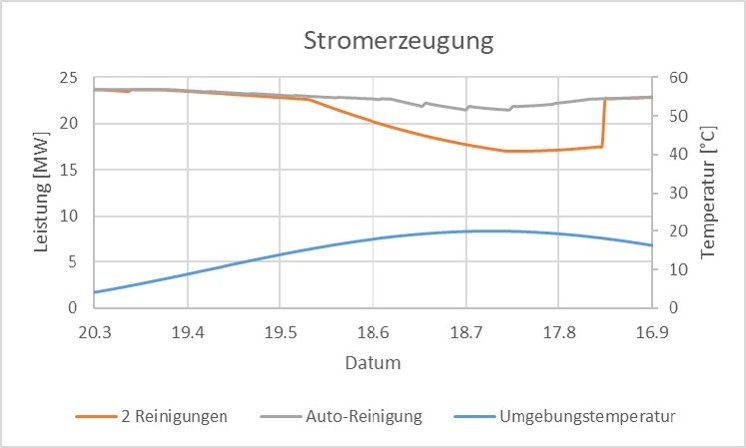

The ControlMaster mycon algorithm calculates the optimal times to clean the heat exchangers based on data available from the customer. This data covers at least the last year, and preferably the last three years. Optimizing cleaning intervals during this period also results in cost savings. Because of this, purchasing a fully-automated cleaning system offers an excellent ROI. Based on mycon's previous experience, the system begins delivering a ROI in 6 – 36 months. Customers can decide on this basis whether a fully-automated cleaning system would be an economical choice for them.

Data transmission / cost calculations with ControlMaster

ControlMaster reviews and processes data received from the customer in a fully automated procedure. The required data and transmission are coordinated with the customer in advance. Calculations are completed quickly, even for large quantities of data. This allows mycon to offer the above calculation at a fixed price of 380.00 euros (three hundred and eighty).

ControlMaster can also be used by the customer to determine the optimal time for cleaning, even independently from mycon. They can then notify the control room of this optimal cleaning time. However, ControlMaster can also start the cleaning process autonomously, with all necessary additional measures if desired.