Automated cleaning with JetMaster AS offers the following advantages over a service company:

- no lead time due to permanent availability of the JetMaster AS,

- no complex construction site equipment, no additional costs for arrival and departure,

- no loss of efficiency of the Air condensers due to constantly available cleaning options,

- resource-saving cleaning process: JetMaster has great cleaning performance through supersonic speed and cavitation effect with extremely low water consumption,

- JetMaster also cleans against the rotor pressure if required.

„We have previously commissioned manual cleaning of our smaller heat exchangers at Kipp Umwelttechnik, the sister company of mycon GmbH. We were so impressed by the performance of the JetMaster process that we requested a fully automated JetMaster system. This system was developed, manufactured and installed by mycon in cooperation with EEW. The fully automated plant for air condenser cleaning offers considerable advantages compared to the up to three annual cleanings with which we have previously commissioned a service provider. The permanent installation of the system and the long-term availability save considerable time and money for the cleaning of our air condensers. The operating costs for the respective cleaning are at a very low level. We plan regular cleaning. That guarantees us the best possible efficiency of our air condenser.“

Key data of the installed JetMaster AS system

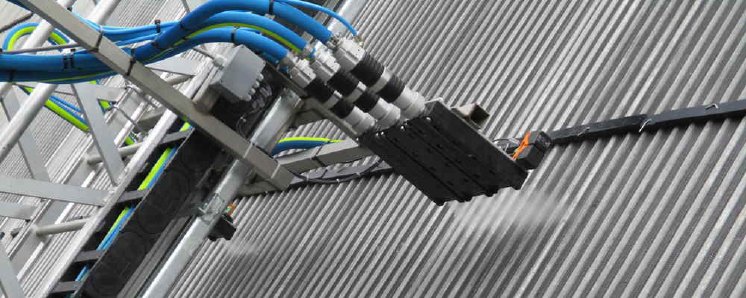

The plant was installed by mycon and Kipp Umwelttechnik on the air condenser fields of EEW Energy from Waste Hannover GmbH. Obstacles located on the surfaces of the exchanger are automatically bypassed by sensors.

Manually used JetMaster method of mycon GmbH

The complete system JetMaster offers four different combination possibilities and can be adjusted exactly to the cleaning task. Even the hardest calcifications and large amounts of residue can be removed. The gentle jet penetrates deep into the equipment without bending / damaging the lamellas. The dirt is gently but effectively removed through the jet from the surfaces. Damage to the lamellar surfaces, as possible with the use of high pressure water cleaning, is completely eliminated when using the JetMaster.

Service, rental, hire purchase or purchase of JetMaster systems

Kipp Umwelttechnik and mycon offer many possibilities. Automated large-scale cleaning systems can also be rented by the plant operator. In this case, mycon can also take over the entire maintenance of the plants. Due to the constant monitoring by remote maintenance systems, possible errors can be detected immediately and partly corrected. In addition, the system can also be reprogrammed via remote maintenance.

Cost driver No. 1 for the manual cleaning service for small heat exchangers is usually the often long arrival / departure to the customer. The arrival / departure often takes more time than the entire cleaning. In the case of large lamellar surfaces, on the other hand, personnel costs and possible downtimes due to shutdown are significantly more important. Timely rental of the JetMaster system can significantly reduce cleaning costs.

Kipp Umwelttechnik and mycon have therefore decided to introduce a special rental system in addition to the cleaning service. For difficult first-time cleaning, the customer will be provided with a co-operating consultant from Kipp Umwelttechnik for instruction and support when renting the equipment on request. Subsequent manual cleaning can then normally be carried out independently by the customer alone or in the automation area at the push of a button.

In addition to the incidental arrival and departure customers have the advantage of renting, manual cleaning equipment within Germany already about 3 days to receive order. The lead time is thus greatly reduced. If necessary, they start the cleaning independently and are not bound to additional dates.

Cleaning heat exchangers with JetMaster on YouTube.

To the videos „JetMaster Automation – outside“ and „JetMaster Automation – inside“ on YouTube.

About Kipp Umwelttechnik GmbH

Kipp Umwelttechnik GmbH is an industrial cleaning specialist for thorough and protective industrial and building cleaning.

Kipp Umwelttechnik GmbH was founded in 1991 as an affiliate of the construction company Jens W. Kipp Tiefbau GmbH, established in 1971. Both companies have always been managed by their founders.

Several business segments of the companies ideally supplement each other for turnkey solutions. Many years of experience and maximum focus on customer problems have resulted in multiple proprietary developments and patents.

In 2002, the Group consisting of Kipp Umwelttechnik GmbH and Jens W. Kipp Tiefbau GmbH was expanded with the addition of mycon GmbH.