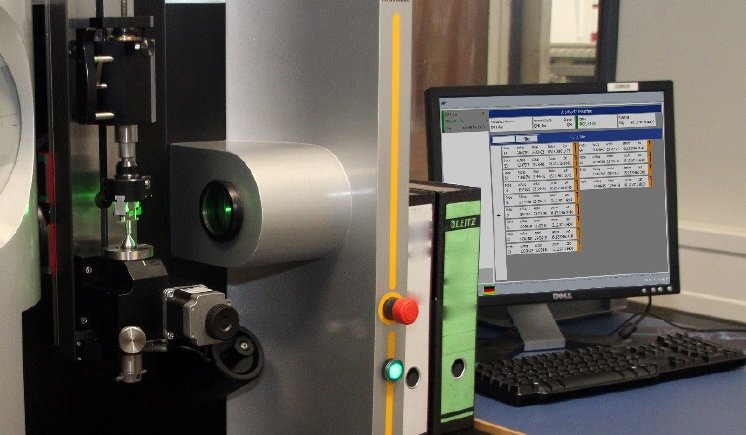

Inspections at special workplaces (e. g. in QA laboratories) have significantly higher demands on the IT than the now widely used employee's self-assessments performed at the machine. The system must especially safeguard, that both the part to be inspected and the notification of the inspection due date are "transferred" from the machine to the inspector. The MES HYDRA from MPDV caters for this by real-time data transmission. The employee in the inspection area can now see the next inspections as well as their inspection due date, which are displayed in the form of inspection points. That enables the inspector, to start the inspection as soon as the corresponding part is available.

Optimized display

In the event, that a large number of inspections are pending, the optimized user interface of the HYDRA shop floor client now offers a sortable and filterable list of inspection points. In the course of the inspection planning the system specifies beforehand, which inspection points are sent to which inspection stations. This greatly simplifies the workflow and allows for a clear inspection process.

General use

Apart from inspection stations in QA laboratories, the new display possibilities and the flexible processes also offer great benefits to the employees at the incoming goods department and to those responsible for the calibration of measuring instruments.

The inspector is perfectly supported by the inspection process that can be adapted to the different test environments at any time. This reduces the time to complete the inspection and reduces inspection efforts. More information on Quality Assurance with HYDRA under: www.mpdv.info/caqen

Like many previous HYDRA extensions, the new features are based on suggestions from the HYDRA Users Group (HUG), an association of dedicated HYDRA users.