Whereas up to now production lines had to be programmed extensively using so-called PLC-based head controls, software-based solutions such as HYDRA Dynamic Manufacturing Control (DMC) from MPDV offer more ergonomics and increased flexibility. The graphic DMC Modeler enables the user to model processes and lines with a few clicks using drag & drop. The models are then imported into the system and simulated in real time.

Factory Model & Manufacturing Instructions

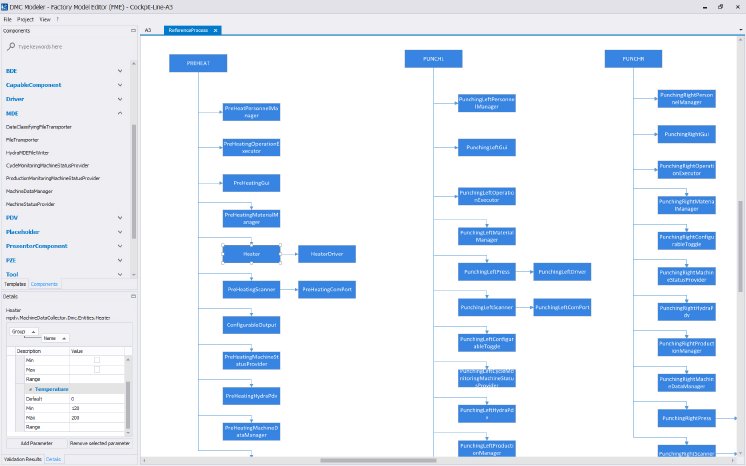

Within the multi-variant sequential production, production lines with several workstations form the basis for the efficient production of products in batch size 1. The new graphic DMC Modeler allows the individual stations of a line together with their peripherals, capabilities and dependencies to be mapped easily. We call the result "Factory Model". Both libraries and templates are available as a basis for this. The operation of the Modeler is similar to that of typical programs for displaying processes and organization charts.

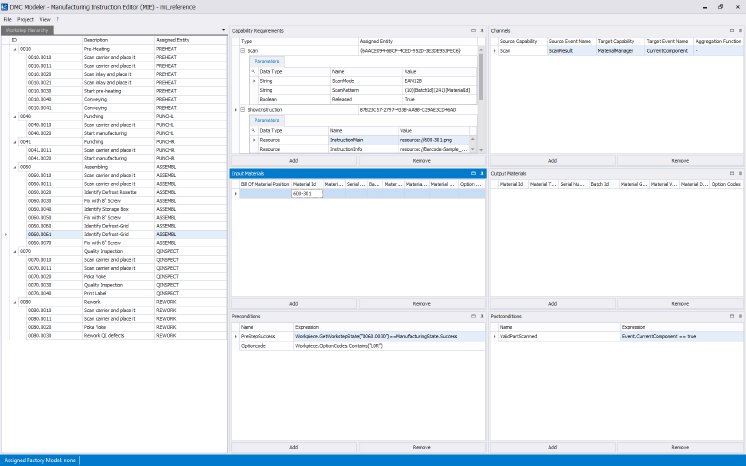

Based on the "Factory Model", the "Manufacturing Instructions" model all the steps required to produce the different variants of a product. The DMC Modeler supports the process engineer in this task by pre-selecting available resources at the individual workstations and by clearly displaying the defined work steps.

Maximum flexibility with a digital image

In combination, the "Factory Model" and "Manufacturing Instructions" determine how the different variants to be produced run through the line and which work steps must be carried out. In this context, we also speak of a digital image of the production line and its processes. Since this image is based on a software solution, changes can be implemented without great effort and, in particular, without programming knowledge. This results in versatile production in the sense of Industry 4.0 and the process engineer becomes the "conductor of production".

More about HYDRA DMC in http://mpdv.info/pmdmcen