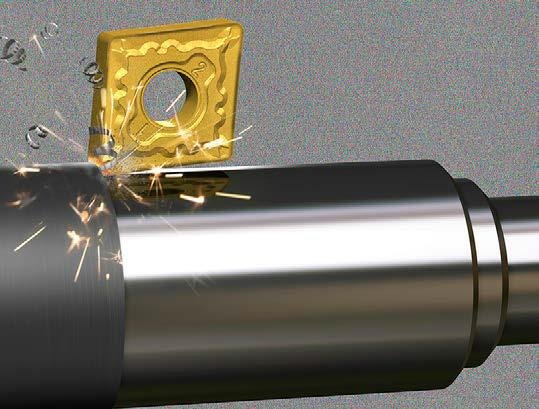

MC6115 has the combination of a high hardness base material and new thick Al2O3 outer coating with improved wear resistance at high temperatures. It also has higher peeling resistance and cutting edge stability achieved by super TOUGH-GRIP technology. This provides the ultimate enhancement of the adhesion between the Al2O3 and TiCN coating layers.

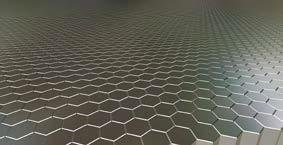

Super Nano Texture Technology

The outstanding crystal orientation of the Al2O3 coating has been developed by improving the conventional Nano Texture Technology. These technological improvements increase both wear resistance and tool life.

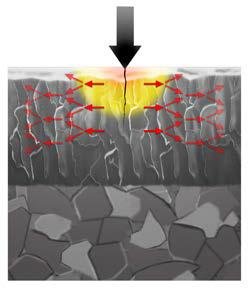

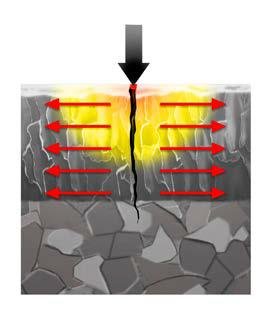

Preventing wear and sudden fracturing

Cracks that occur due to the impacts during unstable cutting are prevented by the relaxation of the tensile stress of the coating. The MC6115 grade decreases the tensile stress by 80% compared to conventional CVD inserts. When cracks are generated in the surface of coatings during machining, they propagate through the coating into the substrate due to the large tensile stress in the coating structure. This creates one of the main causes of sudden insert breakage. MC6115 has a much lower level of stress than conventional CVD coatings due to the surface treatment that spreads the force of impacts during machining and protects it from sudden fracturing.

A new range of possibilities

The combination of the tough substrate and wear resistant coating enables high performance during both high speed continuous and interrupted cutting, thereby permitting a wider range of steel turning applications up to a cutting speed of 480 m/min (Vc).

The inserts are finished in a gold colour for easy identification of used edges and are available in 6 negative geometries, CNMG, DNMG, SNMG, TNMG, VNMG and WNMG, with 11 different chipbreakers.