The side faces have a "Black super-even coating". This is also extremely smooth and stabilises wear development during machining due to reduced friction and helps achieve higher dimensional accuracy of the finished component. Furthermore, the reduced friction prevents abnormal damage such as weld chipping and allows stable machining over prolonged periods.

The carbide substrate has also been developed to work in tandem with the coating layers to provide the best combination. The substrate has an ideal internal composition and distribution of hardness and toughness that offers extreme plastic deformation resistance nearer the surface but also provides the overall toughness required in the core to prevent insert breakage under heavy loads.

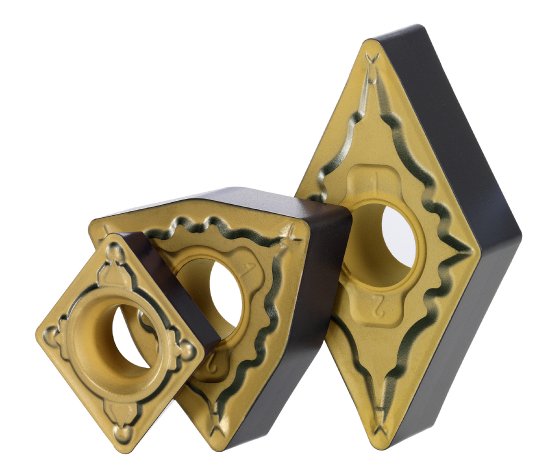

The existing easy to identify, user friendly Mitsubishi chipbreaker geometries, LP for Light cutting and MP for Medium cutting now has a new addition, the RP breaker for Rough cutting. This new RP breaker is ideal for heavier cutting and features a high fracture resistance edge and a sloped cutting face to reduce chip clogging.

Completing the synergy. The combination of carbide substrate and specially designed coating layers, with an optimum choice of chipbreakers allows MC6025 to be chosen as a first P20 recommendation for high speed productivity up to 300 m/min on mild, carbon and alloy steels.

MC6025 is available in a wide range of negative geometries from CNMG through to WNMG types and the series also includes 5º, 7º and 11º positive rake geometries.