Tailored solutions for every fire protection challenge in the wind energy industry - that's the specialism of the Minimax CC Wind / Special Hazard. These solutions result from the smart interaction between innovative technologies used for fire detection, firefighting and fire prevention as well as risk management systems. The special achievement in this regard lies in the engineering and project management of the fire protection systems, conscientious plant construction and dependable service.

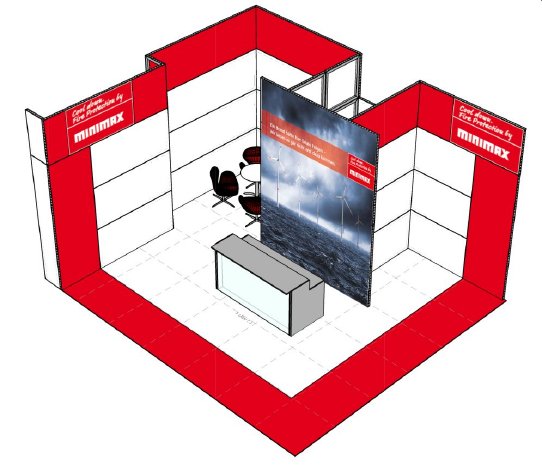

At the trade fair stand at Wind Energy in Hamburg from September 23-26, 2014, Minimax is presenting the most efficient fire protection components for wind turbines: Early detection, leading to the timely start of fire protection measures, is the key focus of dependable fire protection. This is assured by AMX 4004 WEA aspirating smoke detectors for wind turbines, in conjunction with the fire detection and extinguishing control panel FMZ 5000 mod 12. Oxeo inert gas extinguishing systems are ideal for residue-free and environmentally friendly extin-guishing action.

Minimax Aspirating Smoke Detectors: AMX4004 WEA

AMX4004 WEA for wind turbines is a dependable and durable piece of equipment which will withstand vibration as well as extreme variations in temperature and extreme climatic condi-tions: The robust aspirating smoke detector in industrial design is constructed to meet the special needs of wind turbines, because it is particularly resistant to harsh environmental conditions.

A detector like AMX4004 WEA detects fire already in the initial stage by continuous extract-ing air samples from the monitored area. Up to three combinable sensors in a pipe system then analyze the smoke aerosol concentration and optionally the combustion gas concentra-tion as well. In combination with smart analysis algorithms, a comparison with typical interference values is made before triggering an alarm, so that the AMX4004 WEA is extremely error-proof. An integrated air-flow monitoring system also ensures that monitoring functions faultlessly when the switch cabinets are cooled.

Fire Detection and Extinguishing Control Panel FMZ 5000 mod 12

A fire detection and extinguishing control panel is activated by dependable AMX4004 WEA aspirating smoke detectors or interference-resistant UniVario flame detectors. In the event of a fire, the FMZ 5000 mod 12 then ensures that the wind turbine is shut down and activates other programmed control procedures. In addition, the incident is notified to a permanently manned post. If the fire continues to spread and if a further alarm is triggered, the fire detec-tion and extinguishing control panel assumes control to activate the extinguishing system.

The panel also collects all reports and status information, which can be switched at any time to the monitoring system of the wind turbine. Moreover, remote diagnosis and remote control are possible from an outside control room. In case of fire, the panel controls the water or inert gas supply unit. At the same time, it triggers an acoustic and optical alarm and transmits a signal to a permanently manned post.

Oxeo Inert Gas Extinguishing Systems

Fire detection and extinguishing control systems trigger the extinguishing process. Oxeo inert gas extinguishing systems offer particularly effective fire protection for sensitive and high-quality facilities such as wind turbines. Inert gases such as nitrogen (N2), which is common in wind turbines, but also argon (Ar) or mixed gases, extinguish fires in a residue-free and environmentally friendly manner. They are natural components of the ambient air and therefore have no harmful influence on the atmosphere. In addition, inert gases are considered to be non-toxic, are electrically non-conductive and have no chilling effect.

The so-called BAS system makes it possible to set up the cylinder battery in a more flexible and less space-consuming arrangement in an extinguishant control room. Due to leakage monitoring by means of pressure control, the inert gas cylinders can be installed upright, and the nitrogen stored under high pressure reaches even the highest nacelle levels within seconds via a pipe system.

If 3/4-inch extinguishing nozzles are being used, the extinguishant flows at double the rate than with commonly used 1/2-inch nozzles. With only half the number of nozzles, it is possible to ensure the same level of protection. This increases the flexibility of the plant configuration, especially in regard to the design of the piping system. Oxeo inert gas extinguishing systems have a modular design; they are suitable for multizone use and can be adapted to nearly any conversion or extension. After the fire has been extinguished successfully, a wind turbine can be quickly recommissioned.

All Minimax system integration and services, as well as the technologies used are subject to constant quality controls and are certified at least by the independent German testing institution for fire protection and security VdS. The effectiveness of the systems has been tested.

From September 23 to 26, the Minimax Competence Center Wind / Special Hazard presents its portfolio at the Wind Energy in Hall 3, Stand E22.