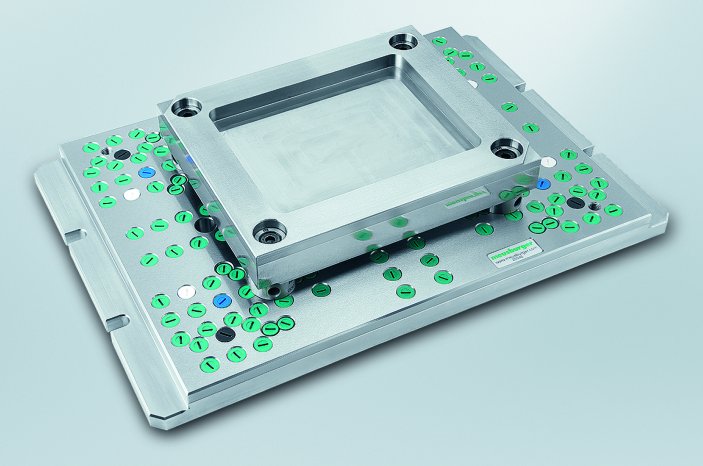

Precise repeat clamping

Due to very tight tolerances, the H 1000 clamping system by Meusburger makes it possible to machine F standard plates with precision on all repeats. This saves a lot of time and money when producing moulds, so the H 1000 clamping plate will break even after just a few moulds. In addition, fitting times are substantially reduced by using the multifunctional clamping system.

Simple and efficient

How it works: The F plates are set using the guide holes and thereby positioned and aligned in the middle of the H 1000. It is no longer necessary to align the plates at regular intervals, so the machinist's work is easier and more efficient. When clamping standard F parts with expanding rings the interfering contour is reduced to the contours of the workpiece. This significantly simplifies the programming and minimises the risk of a collision. The entire surface of the split line face of the cavity plate is accessible for processing.

The benefits of the H 1000 at a glance:

- Improves the quality of your moulds by precise clamping in the µ range for all repeats

- Reduces your processing time by substantially reducing fitting time

- Minimises the risk of collision by using expansion rings for clamping

- The new sizes allows the clamping of all plates up to size 796 996

- Also available in a round version, perfectly adapted to your machine table

Further information: www.meusburger.com