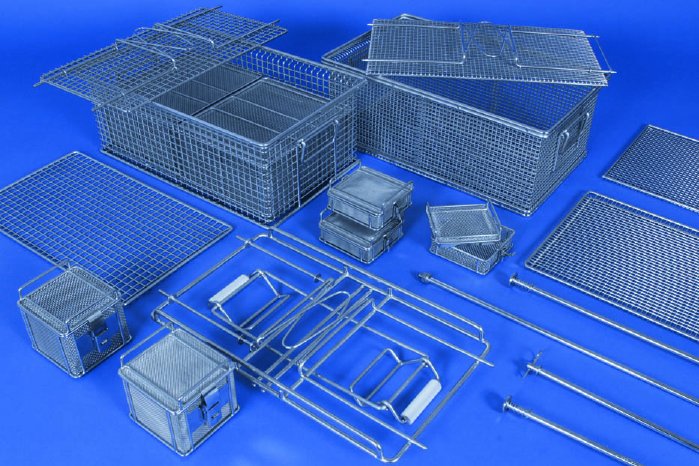

Component cleanness requirements have become increasingly strict in the last few years. Many companies are only able to meet these tougher requirements with increased spending and extra human resources. This is often due to the cleaning basket used. The most commonly used, perforated standard baskets made of galvanised sheet iron prevent effective cleaning of the parts on all sides with cleaning agents, impair the drying process and lead to increased turning and media carry-over. These factors all contribute to a long cleaning time, excessive energy consumption and high costs, while ultimately only offering comparably poor cleaning quality. To eliminate these disadvantages, Metallform Wächter GmbH only manufactures cleaning baskets from stainless steel and predominantly from round wire. This round material ensures that the workpieces can be easily accessed by the cleaning agent from all sides, while making drying faster and minimising carry-over. This results in improved cleaning results in less time, greater throughput, a longer useful tank life and thereby greater profitability.

Perfectly matched standard and customised solutions

With the MEFO-BOX system, Metallform offers a standard solution with a high degree of flexibility. This system, produced in the standard dimensions of cleaning system manufacturers, is available off-the-shelf and is compatible with standard commercial cases and baskets. It consists of cleaning baskets in various mesh widths, inserting bottoms, adjustable lids, clamping lids and supporting lids as well as compartment rods that can be combined in any permutation, which makes the whole system ideally suited to virtually any cleaning task.

The flexible workpiece holder system MEFO-VARIO has been designed to perform cleaning tests with prototypes, samples and pilot series before actual serial production, as well as for diverse ranges of small-batch parts to be produced in alternation. MEFO-VARIO consists of few standard components - a base frame with laser-cut grid, compartment separators, pin inserts, loop inserts and prism inserts – and allows fast and tool-free assembly of workpiece-tailored cleaning baskets that can be used in combination with the MEFO-BOX. To make it quicker and easier to fix the base frame in the MEFO-BOX, it has engaging pins at the front with a spring mechanism on one side. Alongside simple handling, this attachment solution ensures a high degree of process reliability, in particular when the cleaning process involves swivelling and rotating movements.

Customised solutions from Metallform are the ideal alternative when individual construction is needed despite the broad range of standard components in the MEFO program – whether to meet precisely defined cleanness levels, to protect components from potential damage during cleaning, to increase profitability, to optimise the workflow or to automate the process. Metallform manufactures these special, component-tailored workpiece holders as rigid and flexible solutions. The rigid model enables maximised process reliability. Flexible special solutions can be adapted to different workpieces thanks to their detachable, part-specific inserts. They are primarily used for components with a short product life cycle.

Fast return on investment

Through many years of experience and intensive cooperation with cleaning system and cleaning agent manufacturers, Metallform is able to develop and manufacture the optimum cleaning and transport basket for any cleaning task. And thanks to their minimised changeover procedures for parts and optimised logistics, the company's solutions also allow a faster return on investment.

Please contact Metallform Wächter GmbH, Gewerbestrasse 35, D-75015 Bretten, Germany for more information. Tel: +49 (0)7252 9426-0, Fax +49 (0)7252 9426-11, www.metallform.de.

- - -

We would be grateful to receive a copy of any publication featuring content from this release. Contact for editorial offices:

SCHULZ. PRESSE. TEXT.

Doris Schulz

Martin-Luther-Strasse 39

70825 Korntal, Germany

Tel: +49 (0)711 854085

Fax +49 (0)711 815895

E-mail ds@pressetextschulz.de

Member of Absolut … Network

METALLFORM Wächter GmbH

Anja Wächter

Gewerbestrasse 35

75015 Bretten, Germany

Phone: +49 (0)7252 9426-10

Fax +49 (0)7252 9426-810

E-mail anja.waechter@metallform.de

www.metallform.de