In all areas of technology, manufacturing residues such as fats, oils, emulsions, dirt and turnings have to be cleaned from components. Standardised cleaning baskets made of galvanised sheet iron are predominantly used for this. These baskets have different degrees of perforation, yet due to their construction using sheet metal and angle profiles they collect a large volume of turnings and cleaning media, virtually cut off ultrasound in the cleaning tanks and only provide for a minimal rinsing or spray effect by the cleaning media. What is more, the drying of the cleaned parts is severely impaired by the sheet walls. These factors combined result in long cleaning times and correspondingly high cleaning costs for comparably inadequate cleaning quality. Such problems particularly apply to cleaning with alkaline/aqueous media, in addition to cleaning with hydrocarbons and halogenated hydrocarbon. The cleaning basket therefore often holds the potential to optimise results, times and costs within the cleaning process.

Optimal design

For reliable and fast removal of contamination, it is essential that the parts in the basket are optimally accessible. This is the only way to ensure that the cleaning medium reaches the workpieces evenly, allowing the washing mechanism to work to full effect and films and particles to be washed out as thoroughly as possible.

Metallform Wächter is vastly experienced in the development, design and manufacture of economical, high-tech cleaning baskets, enabling it to take a large number of cleaning-related factors into consideration. Such factors include preventing the cleaning baskets from scooping and carrying over cleaning media, guaranteeing that turnings and particulates are washed away as thoroughly as possible, ensuring optimal accessibility for ultrasound and drying with compressed or hot air, full compatibility with standard commercial goods boxes and transport boxes, possible use as immersion, lifting, rotating, or rocker basket and a stable structure with a stacking capacity of up to 300 kg.

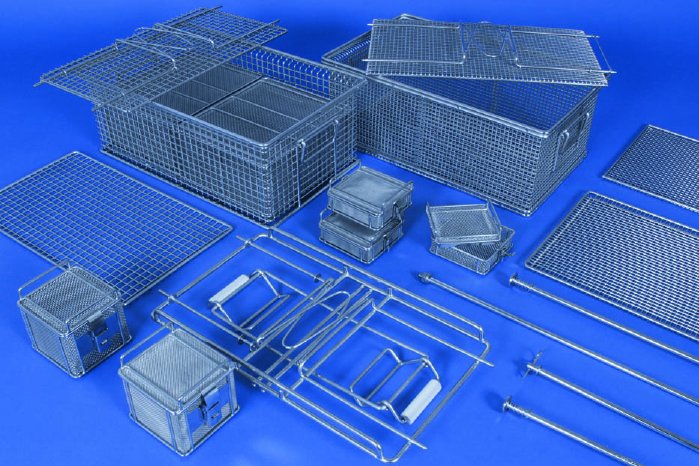

MEFO-BOX – a standard system with a high degree of flexibility

The geometry of the parts and components that have to be cleaned is a significant aspect. The particular difficulty in designing cleaning baskets is that despite the immense variety of parts, solutions have to be found that enable optimal cleaning of assembly parts through their universal design and therefore limit the number of cleaning baskets required to a minimum for economical and logistical reasons. Under strict adherence to the catalogue of requirements described above and based on extensive experience with cleaning problems in all areas of technology, Metallform has developed the MEFO-BOX system. This is a coordinated programme of cleaning baskets that can be expanded with a diverse range of accessories to meet the customer's needs. Alongside standard components such as inserting bottoms, adjustable lids, clamping lids and supporting lids, compartment rods and separators, and bulk material baskets, appropriate special trays are also used. They enable sensitive parts to be cleaned without them coming into contact with one another.

Customised solutions that perfectly suit requirements

Whether your goal is to maintain a precisely defined degree of cleanness, protect components from damage during cleaning, increase efficiency, optimise your workflow or automate your process, Metallform develops and manufactures the optimum technical and economical solution for every application. The dimensions of these workpiece holders are individually adapted to the parts to be cleaned and the needs of the corresponding cleaning system or system operator. Metallform offers these systems in a variety of designs: the rigid model enables maximised process reliability. It is usually used for components that are produced in large batches over a long period of time. Flexible MEFO special solutions can be adapted to different workpieces thanks to their detachable, part-specific inserts. They are primarily used for components with a short product life cycle. The flexible model also offers advantages if the range of parts is constantly changing.

Made from stainless steel

The cleaning baskets and workpiece holders from Metallform are produced from stainless steel rounds with an electrolytic polished surface as standard. The high-quality, long-life material is suitable for all cleaning media and prevents return contamination from the basket to the component as well as contamination of the tanks due to corrosion and zinc separation. The use of rounds offers clear advantages for the cleaning process: The parts are easily accessible to the cleaning media on all sides. The round material offers optimum drainage behaviour, which minimises the carryover of dirt and cleaning media. And the round wire also minimises the contact surfaces. But the workpiece holders not only offer uncompromising quality in terms of the design and material, but also in finishing. All connections of the rounds are completely welded. There are no sharp corners, edges or wire ends that could cause injury.

Further Information: Metallform Wächter GmbH, 75015 Bretten, Germany, phone +49 7252 9426-0, www.metallform.de

Thank you in advance for sending us a specimen copy.

Contact for editorial offices:

Metallform Wächter GmbH

Anja Wächter

Gewerbestraße 35

75015 Bretten, Germany

Phone +49 (0)7252 9426-10

Fax +49 (0)7252 9426-810

e-Mail anja.waechter@metallform.de

www.metallform.de

SCHULZ. PRESSE. TEXT.

Doris Schulz

Martin-Luther-Straße 39

70825 Korntal, Germany

Phone +49 (0)711 854085

Fax: +49 (0)711 815 895

e-Mail ds@pressetextschulz.de

Member of Absolut… Network