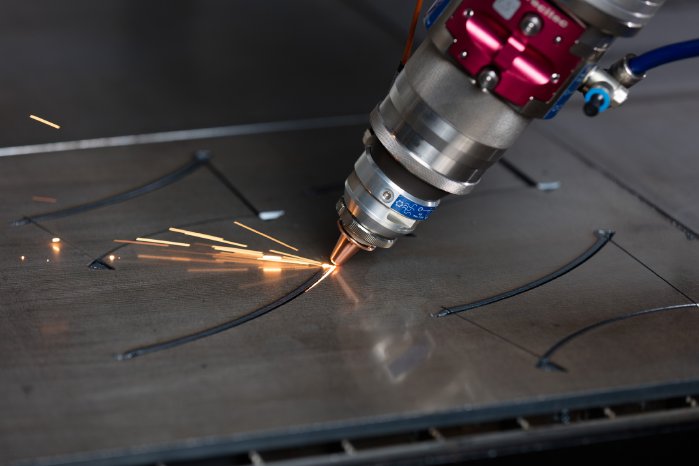

Precision laser cutting of large steel sheets weighing tonnes requires powerful equipment. The LaserMat® II from Messer Cutting Systems GmbH has been conceived for exactly the requirements of large sheet processing with the CO2 laser. The on-board laser power source (resonator) permits working lengths of up to 50 m and even more, with working widths of up to 4500 mm. The optical beam path compensation keeps the length of the laser beam constant when cutting, even with transverse axial motion, and thus ensures the highest cutting quality over the entire working area. Large components, for example out of Mild Steel up to 25 mm thick, or Stainless up to 20 mm thick, can thus be cut in one operation without defects in the contour. Also direct loading of large special formats and parts with a crane is possible without any problems thanks to the on-board light barriers and laser protection hood (Laser protection class 1).

In order that the cutting operations proceed quickly and precisely the cutting program is rotated in the control according to the actual position of the plates. The cut then takes place with an accuracy of 0.1 millimetres. The high positioning and repetitive accuracy of the machine is achieved by Messer through perfectly matched functional factors. These include, for example, the track designed specifically for laser and the robust linear guides. Apart from precision, the acceleration forces of up to 0.5 g and a simultaneous axes speed of up to 140 m/min give excellent speed and dynamics. The real time control generates short piercing times and ensures the finest micro-stiches.

Further, the infinitely rotating bevel head with magnetic collision protection facilitates continuous bevel cutting from -45° to +50° - even on Stainless Steel, thanks to the special nozzles. The integrated colour camera allows the process to be displayed directly on the screen of the central operating terminal. Identification of the parts also has ever increasing importance. Apart from standard laser marking, other processes are also possible here such as marking with micro punching. Thus centre points, marking lines as well as figures and letters can be made visible at high speeds.

More under www.messer-cs.de