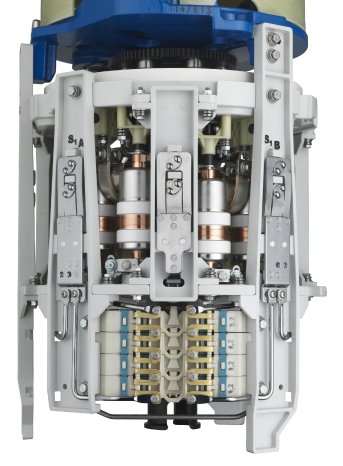

The safe and reliable operation of electrical transmission networks places ever increasing demands on voltage and load flow control. At the same time, an increase in efficiency is high on the agenda. Maschinenfabrik Reinhausen GmbH (MR) offers an effective response to these rather contradictory goals with the new VACUTAP® VM. The core field of application of the innovative on-load tap-changer in vacuum switching technology is in transformers from 30 to 200 MVA and the voltage levels of 110 to 230 kV that are typical in the transmission network. However, it can also be used to full potential in arcing furnaces, high-voltage direct-current transmission (HVDC), electrolysis, rectifier and phase shifter applications. What’s more, it is just as effective when used in new transformers as it is in existing oil transformers that have been modernized.

Faster and simple exchange in plug-and-play procedures

The new VACUTAP VM is retrofitable and enables fast, simple change from oil to vacuum switching technology. The connection compatibility of the diverter switch insert to the OILTAP® M/MS ensures that not only the original of one of the most frequently used on-load tap-changers in the world can be exchanged in a plug-and-play procedure, but also similar models based on previous license or non-authorized models can be exchanged in this manner.

Maintenance-free operation in network applications

In the development of the new VACUTAP® VM, the focus is on minimum maintenance requirements and maximum reliability. The results are very impressive – the maintenance interval of 300,000 switching operations, which is both electricity-independent and time-independent, as well as the contact life of 600,000 switching operations, guarantee practically maintenance-free operation of the tap-changer over the entire service time of the transformer in almost all network applications. The lifespan of the diverter switch unit is actually 1.2 million switching operations. In addition, the on-load tap-changer oil is not polluted by the arc extinction as a result of the vacuum switching technology used, which means that neither an oil filter system nor the associated filter changes are required. In addition to a high degree of availability of the transformer, this also leads to lower operating costs.

Interrupter exchange module – faster change of vacuum interrupters

Unlike network operation, up to 200,000 tap-change operations per year are typical in heavy duty applications, such as arc furnaces, HVDC, electrolysis and phase shifters. The interrupter exchange module contributes to reductions in production downtimes due to maintenance when exchanging the vacuum interrupters after 600,000 tap-change operations. This intelligent spare part solution consists of a completely assembled and preconfigured module including a supporting unit, which enables a simple, time-saving change, thus ensuring fastest renewed availability of the transformer.

Arc control system – the operational reliability advantage

Absolutely reliable extinction of the arcing is an essential prerequisite for the trouble-free and damage-free operation of on-load tap-changers and transformers. The arc control in VACUTAP® VM performs this function. In this unrivalled protection system, the vacuum interrupters – which have been specially developed for use in tap-changers – in advanced interrupter technology, a recently patented kinematics of operation and the complete switching sequence have been optimally adjusted to each other. This ensures that the arcing is extinguished even under extreme network conditions.

Step protection – optimized overvoltage protection

The step protection system is also unique in this class. It reliably protects the diverter switch from a short-circuit between taps in the event of overvoltages in the network, due to lightning and switching operations, for example. In contrast to the spark gaps that are normally used for this function, special components from semiconductor technology are used in the step protection system. This results in a lower dispersion of tripping values, so that optimum insulation coordination within the diverter switch is achieved and damage to the insulation is prevented.

Various versions of the new VACUTAP® VM are available and are designed for selected alternative insulation liquids ex works. The new VACUTAP® VM is also suitable for operation in earthquake-prone areas. In addition, the planned ATEX certification will also enable usage in explosive areas. Further information at www.vacutap-vm.com.

VACUTAP®, OILTAP®, arc control system™ and step protection system™ are trademarks of Maschinenfabrik Reinhausen GmbH.

- - -

About Maschinenfabrik Reinhausen GmbH

Maschinenfabrik Reinhausen GmbH (MR) is the largest company in the Reinhausen Group, with regard to both sales and the number of employees. Founded in 1901, MR, with its headquarters in Regensburg and 22 locations around the globe, is the leading global premium manufacturer of on-load tap-changers for regulating power transformers today. Worldwide, more than 50% of current flows through MR tap-changers.

We look forward to receiving a sample copy or link of all publications. Thank you.

Press Contact:

SCHULZ, PRESSE. TEXT., Doris Schulz, Martin-Luther-Straße 39, 70825 Korntal, Tel: +49 711 854085, doris.schulz@pressetextschulz.de, www.schulzpressetext.de

Maschinenfabrik Reinhausen GmbH, Kerstin Lochner, Falkensteinstraße 8, 93059 Regensburg, Tel: +49 941 4090-5238, k.lochner@reinhausen.com, www.reinhausen.com