The clincher, what is truly extraordinary about this arbour holder is the rotating centre that swivels down under NC program control. It can be swivelled down 90° for front-side machining. In addition to 5-axis circumferential machining, this also facilitates front-side machining and ensures complete processing without any clamping changes.

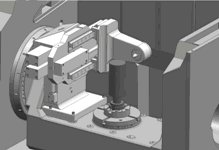

The arbour holder is adapted on the side to the NC swivelling rotary table of a 5-axis C 30 U or C 40 U machining centre next to the table plate (see 6000.jpg). The rotating centre can be lowered to the workpiece automatically to hold the workpiece in place (traversing range 220 mm), thus ensuring optimum support. Workpieces can be clamped and machined up to a length of 420 mm with a maximum collision circle diameter of 420 mm. The diameter is not actually relevant, since mostly thin workpieces require support. If the arbour holder is swivelled down, larger bulky workpieces can also be machined conventionally with 5 axes. Thus the user is not at all limited, having acquired a high-quality 5-axis machining centre of extreme precision with an automatic arbour holder option.

Hermle HS 30 handling system or a Hermle robot system can be adapted to the machining centre to insert blanks and remove manufactured workpieces. This ensures long machine times with no operator intervention in 2- or 3-shift operation.

Facts:

- NC arbour holder with program-controlled swivel-down rotating centre

- Circumferential and front-side machining in a single clamping setup

- 5-axis machining centre with built in NC swivelling rotary table

- Usual Hermle modified gantry design ensures compact construction

- High-performance Heidenhain iTNC 530 / Siemens S 840 D control technology

- Can be automated with Hermle robot system or Hermle HS 30 handling system