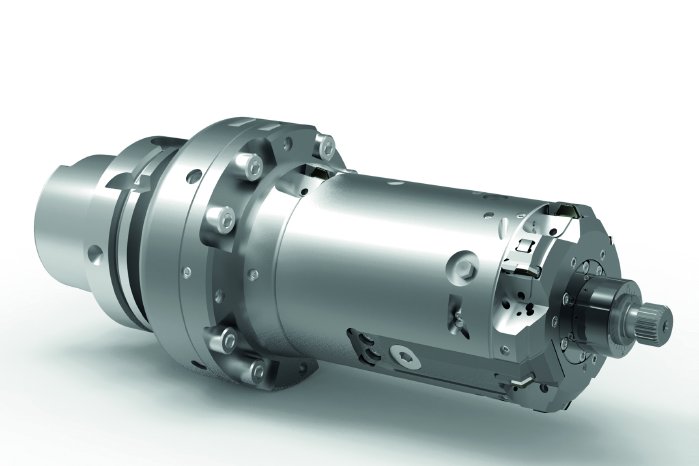

Conditioning of the cylinder bore surface with PCD contour bladesFor this new technology, MAPAL has developed new tools for the pre-machining and conditioning of the cylinder bore surface before thermal spraying in order to ensure optimum coating adhesion. PCD contour blades are used to create a defined structure on the cylinder bore surface with which the sprayed coating can optimally interlock and adhere itself. The structuring needs to have small undercuts and at the same time be designed to prevent blistering or inhomogeneity in the sprayed coating.

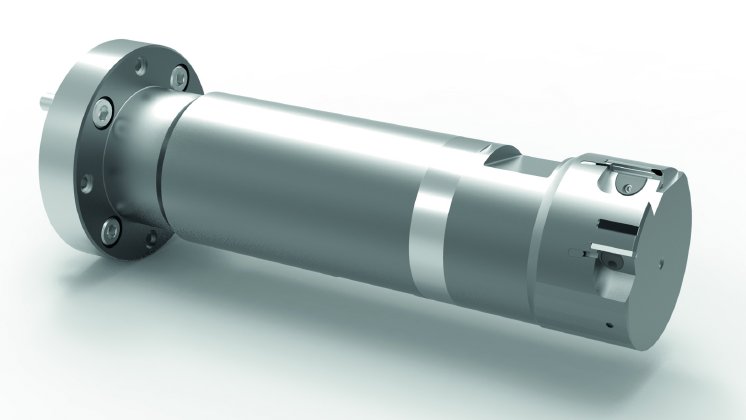

Fine machining tool with HX blades as preparation for precision honingAfter the spraying of the coating, the cylinder bore surfaces are machined using fine boring tools with HX blades. The geometry of the bore surface is thus prepared for the final precision honing. Tools with PcBN blades are used here, as the very hard sprayed coatings place a very high load on the cutting edges. As with other applications in hard machining, the know-how in the choice of the right PcBN grade and the edge preparation are crucial for success. The fine machining tool is furthermore equipped with coolant-controlled actuator mechanisms and cutting compensation.

Caption:

Picture 1: Conditioning the cylinder bore surface with fine boring tools with PCD contour blades

Picture 2: Fine machining the cylinder bore surfaces before precision honing with fine boring tool with HX blades. The rough honing process can be eliminated.