The housings consist mainly of alloy diecast aluminium (AlSi9Cu3Mg). Demands for high quality are placed on their manufacturing. The tolerances of cylinder form < 8 μm, roundness < 4 μm and surface finish with Rz < 3 μm have to continually and reliably be achieved during production. These requirements are particularly put upon the mostly stepped valve bores. Their machining is divided into several machining sequences. In these situations, different tools are used for piloting, semi-finishing and finishing.

Since not every valve bore requires the maximum manufacturable precision, alongside the finely adjustable boring tools MAPAL also offers permanently brazed PCD fine boring tools which achieve a considerable reduction in process time, despite a tolerance range which is only minimally extended. In addition, the fixed multiple-bladed tools display their quality by eliminating the fine adjustment of the cutting edges, thereby minimising adjustment efforts.

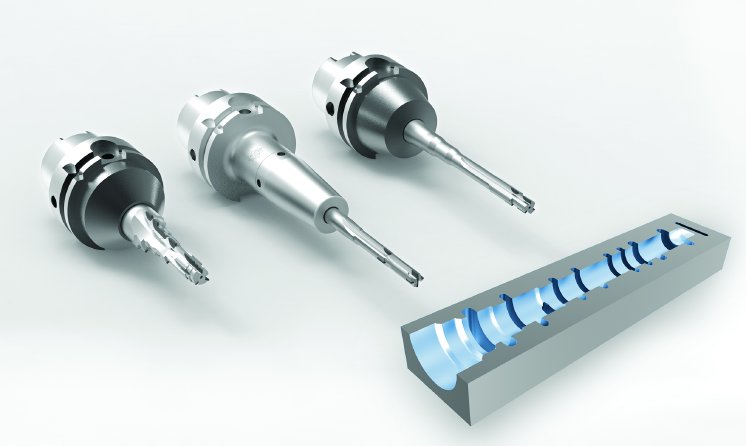

Four cutting edges for a significantly shorter process time

For intermediate machining, a four-edged PCD tool with brazed cutting edges has been developed; which can be used as an alternative to a twin-edged standard tool as long as the length/diameter ratio as well as the stock situation allows. A significantly shorter process time and the required positional accuracy are thereby achieved. This is the basis for finish machining.

The outcome of the finishing depends largely on the quality of the intermediate machining. Previously, the high standards placed upon finishing work had been met by using a single-bladed finely adjustable PCD fine boring. Again, a new reliable and economical machining strategy has been designed. Depending on the requirement, three- to six-edged, fixed PCD fine boring tools are available for finishing work. These provide a significant improvement in cycle times with almost the same precision.