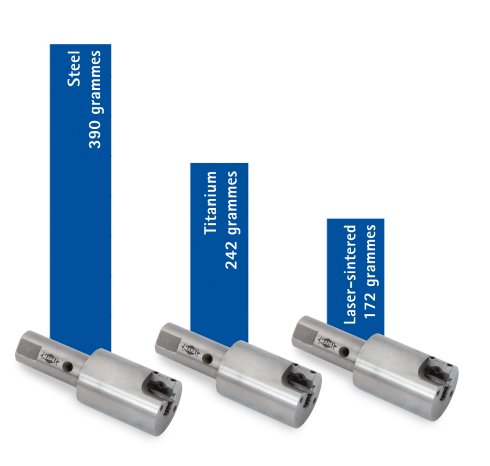

Weight optimisation thanks to laser-sintered tools

External reamers function better, the lighter they are – particularly when machining shafts with small diameters. However, a conventionally manufactured steel tool for the machining of a diameter of 8.5 mm already weighs 400 grammes. This weight and the resulting inertia considerably limit the maximum possible cutting speeds. Weight optimisation of the tools immediately brings noticeable increases in productivity. MAPAL is one of the first companies in the industry to use the additive production process of laser sintering to optimise the weight of the external reamers. Thanks to a specially developed rib structure inside the tool (patent pending) it is now possible to produce the above-mentioned reamer with a weight of 172 grammes, i.e. to more than halve the weight. Machining with the laser-sintered external reamers can now be carried out far faster and with higher precision.

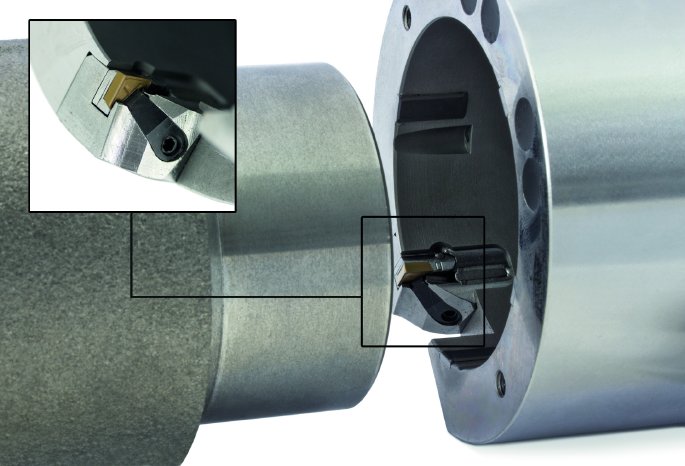

Simple handling with the EasyAdjust-System

Optimum adjustment of the blades is a challenge during external reaming, as the blades are inside the tool and are very difficult to access. The EasyAdjust-System offers the optimum solution here. An innovative cassette with integrated back taper completely eliminates the need for adjustment for the back taper of the minor cutting edge. The integration of the EasyAdjust-System into the external reamers thus makes the technology even more cost-effective.

Adaptive floating holder corrects axial offset

When using reamers on lathes, axial errors frequently occur between the adapter and the bore to be machined. MAPAL therefore recommends the use of floating holders which correct the axial offset. A floating holder offers a significantly improved process reliability particularly if the offset changes continuously due to the thermal expansion of the machine or due to different positions on cycling the revolver. The new adaptive floating holders can be ideally adapted to the application in deflection direction, floating stroke and deflection force. Reaming operations with stationary tool thus achieve a far higher productivity.

Illustrations:

Ill 1: Optimisation through laser sintering: Weight of the external reamers more than halved.

Ill 2: The EasyAdjust-System significantly reduces the handling of the external reamers.