The greatest advantage of HSK-T compared to existing systems is the very quick, straightforward tool change. While with the standardised connections used in the past, 10 to 15 minutes were often necessary for the tool change, with HSK-T the time required is reduced to less than 30 seconds. Paired with very high changeover accuracy, there is a significant reduction in the machine downtimes and as a result a significant increase in productivity for the user. Along with complete conversion, it is also possible to partially convert existing revolvers. On stations with frequent tool changes, conversion to HSK-T is particularly advantageous, as the investment is manageable and pays for itself in a short time. MAPAL offers conversions from all common connections on lathes to HSK-T, across machines and independent of manufacturer, as well as a wide range of turning holders.

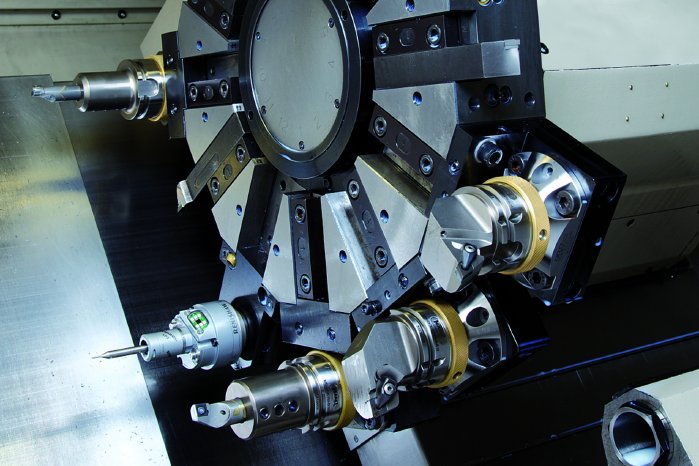

Conversions for lathes offer higher accuracy with increased productivity

The greatest advantage of HSK-T compared to existing systems is the very quick, straightforward tool change. While with the standardised connections used in the past, 10 to 15 minutes were often necessary for the tool change, with HSK-T the time required is reduced to less than 30 seconds. Paired with very high changeover accuracy, there is a significant reduction in the machine downtimes and as a result a significant increase in productivity for the user. Along with complete conversion, it is also possible to partially convert existing revolvers. On stations with frequent tool changes, conversion to HSK-T is particularly advantageous, as the investment is manageable and pays for itself in a short time. MAPAL offers conversions from all common connections on lathes to HSK-T, across machines and independent of manufacturer, as well as a wide range of turning holders.