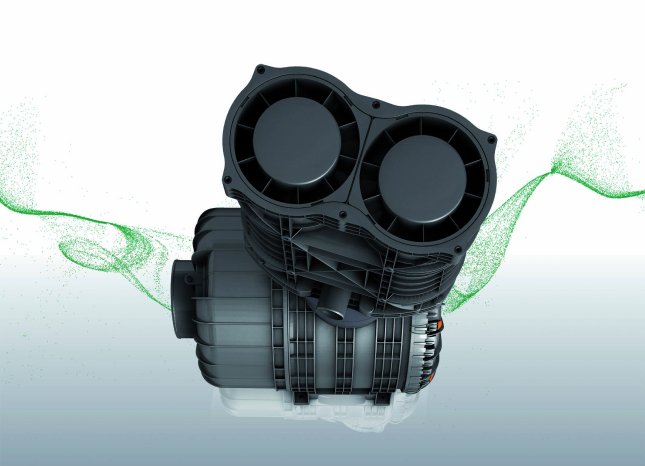

At the Agritechnica 2013 trade fair MANN+HUMMEL will present the single and two-stage air cleaners ENTARON MD and ENTARON XD for air requirements of 40 cubic metres per minute. The two big sizes for the ENTARON series were developed for construction machines, agricultural machines, gensets and mobile compressors with an engine output up to 450 kW.

The new forage harvester series BiG X 480 and BiG X 580 of the machine producer Maschinenfabrik Bernard Krone GmbH (Spelle) are two of the first series applications for the two-stage ENTARON XD 40. "The product has impressed us: the robust two-stage air cleaner made in plastic replaces a metal air cleaner and therefore contributes to weight reduction in the vehicle. Further important advantages are the long service life in comparison to metal air cleaners and the easy servicing without tools of the main and secondary element", explains David Gebing, development engineer at Krone responsible for engine intake filtration.

The flow resistance design of the ENTARON MD 40 has been improved and as a result is particularly suitable for applications such as stationary compressors or gensets. In applications with harvesting machines it can be combined with a separate pre-separator, whereby the pre-separation and main filtration are separated from each other. The advantage is a longer service life for the main filter in the field. For this purpose the filtration specialists from MANN+HUMMEL recommend the new DualSpin XT pre-separator which is offered in addition to the established DualSpin. DualSpin XT is characterised by an extremely compact design and integrated mounting points.

The complete ENTARON series includes 8 products which cover nominal flow rates from 7 to 40 cubic metres per minute (m3/min). The ENTARON has a compact design. The compact design is supported by a bracket integrated in the housing and a locking system accessible from the end of the air cleaner. The three-part design of the housing offers flexible positioning of ports in relation to the bracket. The integrated bracket allows nearly all possible variations for the port position. The two-stage ENTARON XD version of the air cleaner achieves a pre-separation efficiency without scavenging of up to 85%.

User friendly and easy to service Servicing the ENTARON XD / MD is easy by unlocking the fasteners on the end of the air cleaner. The fasteners are highly visible and snap into place and are not in the way when removing or replacing the servicing cover.