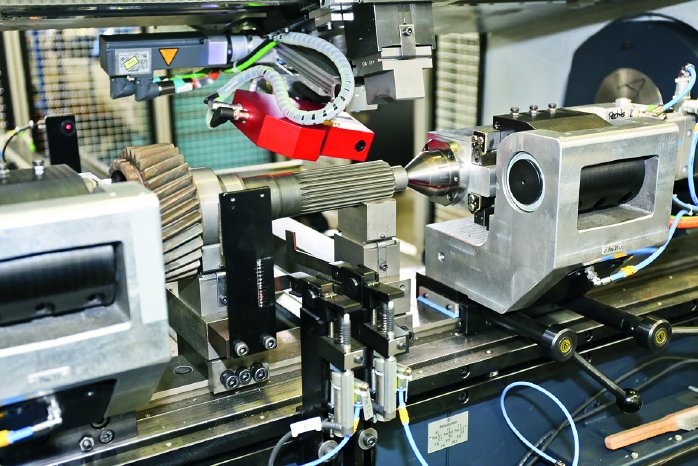

TRILOS, a system for all tooth angles

The TRILOS laser measuring system and its runout measurement software are integrated in the M-AH control. While the shaft is rotating, runout errors are precisely measured in the gear teeth: with high resolution and frequency. The advantage compared to conventional measurement with expensive master gears: the system measures wear-free. A further advantage: the system can be used for all tooth angles of running gears as well as for splines.

Automatic resetting, also with large differences in workpiece lengths

The RIVLEX system is used in M-AH straightening machine for automatic resetting from one batch to the next – also with large differences in workpiece lengths. RIVLEX axially positions and clamps workpiece supports, measuring devices and anvils. Components that are not needed are automatically “parked out”.