Here are just a few of the exciting UI developments in Gocator 6.0:

- Tools Diagram for Easy Viewing and Managing of Relationships Between Tools

- Multi-Measurement Data Viewing for Increased Workflow Efficiency

- Multi-Window Data Viewing for Faster Development and Troubleshooting

- Dashboard Data Viewing for Greater Visibility into Measurement Results

In addition, users can now integrate Universal Robots (UR) with Gocator® 3D laser line profile sensors.

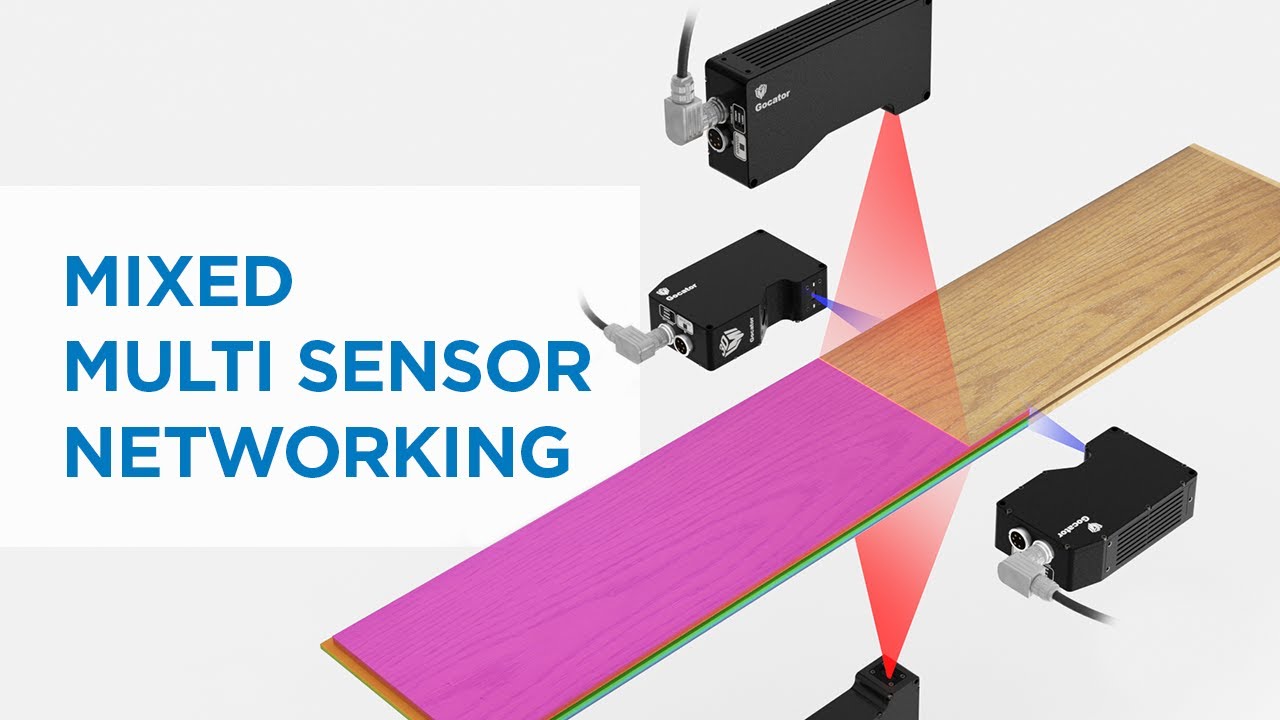

“Gocator 6.0 delivers major user interface improvements that make 3D measurement and inspection more efficient and intuitive than ever before. Features like the Tools Diagram, multi-measurement data viewing, and multi-window data viewing give customers more flexibility and control over their inspection process. In addition, mixed model multi-sensor networking and support for UR robot integration with Gocator line profilers provide extended options for system configuration and greater factory automation,” said Chi Ho Ng, LMI Technologies Senior Director of Technology.

Other new tools and improvements for you to explore include:

- Enhanced Data Viewer display that merges 2D intensity with 3D height map data for more complete data visualization

- Refreshed Emulator Scenario Selection Menu offers greater choice and an improved user experience

- Surface Blob tool for advanced 3D height map and 2D intensity surface defect detection (e.g., uneven or excess material, gouges, blemishes)

If you already own a Gocator®, you can download firmware 6.0 and upgrade your sensor for free here.