iLux lighting systems are used for visual quality control of components and strip material, for example, car body or cockpit components, instruments, wafers or parts made of fibre composite material.

The surface of a product is often a key quality criterion – just a small scratch might decide about loss or profit of a sold item. In situations where a large number of different items, complex geometries, small lots or bright surfaces are produced, inspection based on image processing is often not an economically viable option, due to the high purchase, maintenance and adaptation costs of such systems.

Under these circumstances human qualities are demanded: with the right illumination a human inspector can instantly recognize and assess surface defects, without having to adapt any software or hardware. Moreover, he can pick up individual items and view them from all sides. The use of mirror optics enables him to even see undercuts.

For Heinz Hahne, Managing Director of LDV-Systeme, visual checks are a highly valuable complement to automatic surface inspection systems. “In spite of all progress in the development of hardware and algorithms, it will always be up to the human operator to make the ultimate decision about the classification and severity of a defect.”

Visitors to “Vision” can put the system to the test directly at the fair booth of LDV-Systeme. They are invited to bring their own work pieces and check them by means of the lighting systems installed at the booth.

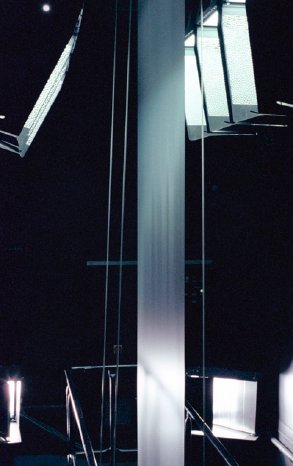

The patented Lichtsegel® (“light sails”) reflect directional, quasi-parallel light onto the surface, making defects clearly visible. Also small and faint defects and those spreading over a large area, for example, scratches, impressions or colour variations, become visible.

Inspection workstations from LDV-Systeme are ergonomically designed. In order to enable concentrated, non-tiring work over a long period, the light intensity is adapted to the human eye, i.e. the systems work with low light.

Light sail systems are in operation worldwide at leading manufacturers and they prove their worth day in, day out, for example, in the automotive industry, at suppliers to the automotive industry as well as in steel and NF-metals rolling mills.

In addition to its patented lighting systems, LDV offers a broad portfolio of services, including the design of ergonomically optimized workstations and the maintenance of the installed systems – from cleaning through to the readjustment of the light sails.