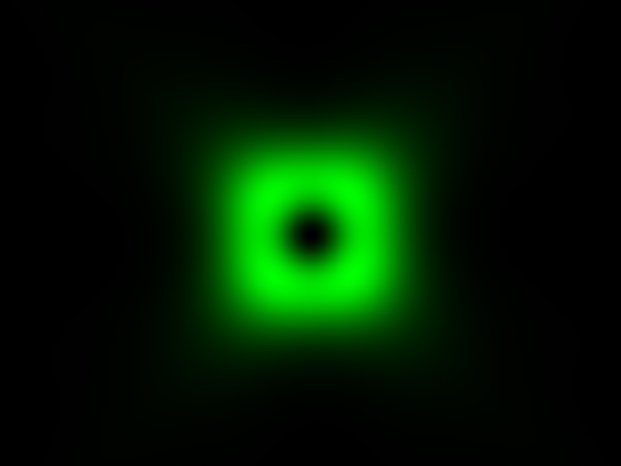

Vortex DOEs are enjoying increased popularity. These components put very few demands on the laser beam and on the distance to the working area. Another advantage of these components is the intensity distribution of the laser beam: A laser beam features the highest beam intensity at its center. The Vortex element "redirects" the power to the edges to achieve a higher efficiency of the overall system.

LASER COMPONENTS distributes the diffractive optical elements in Germany and the US.

More Information

http://www.lasercomponents.com/...

Trade Shows

Security + Defence, Sept., 24 - 25, 2013, Internat. Congress Center Dresden, Germany, Booth 304

enova - OPTO, Oct., 08.-10., 2013, Paris Porte de Versailles, France, Booth L9

PHOTONEX 2013, Oct., 16.-17., 2013, Ricoh Arena, Coventry, UK, Booth D20

BiOS EXPO 2014, Feb., 01.-02., 2014, The Moscone Center, San Francisco, USA, Booth 8517

Photonics West 2014, Feb., 04.-06., 2014, The Moscone Center, San Francisco, USA, Booth 517