The new Super-Hydrophobic-Module (SHM) is a milestone for perfect print with higher density even on super hydrophobic lenses. This SHM module optimises printing results and generates an abrasion proof homogeneous appearance.

Furthermore adhesion raised and drying time has been reduced to some seconds.

Ink removing is a simple job the optician manages with the routine solvents.

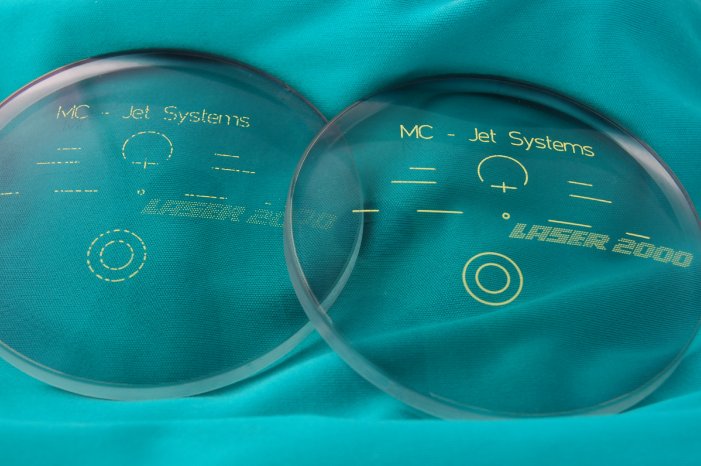

Besides the capability for round lens handling the new MC-Jet systems are determinated even to handle lenses with a complex shapes and diameters.

MC-Jet system design allows integration of function modules like measurement- and inspection as well as laser engraving technologies and individual customised components.

These extensions expand the MC-Jet systems to highest flexibility and make it adaptable to any individual RX lab.

This reasonable and high resolution non contact printing technology for permanent as well as temporary printing has been developed from Laser 2000 GmbH in cooperation with 3D-Micromac AG. It is patent pending and has become a trendsetter within the last years. More info: www.laser2000ophthalmic.com

Typical MC-Jet characteristics

- Individual marking of mixed contents

- High flexibility by waiver of clichés

- Touch less printing

- No slip or distortion on convex or concave lenses

- No (!) cliché costs

- Minimum ink consumable costs

- Environment protection by low solvent consumption