To meet increasing demand from lens manufacturers for more compact, self-contained systems the MQ-JET 01 will be equipped with a full-feature, measurement and control station with new capabilities that deliver greater speed, traceability and marking quality.

The classic methods for optical measurement in RX processes are systems for dioptre measurement for single vision or free form lenses. In most cases these systems are supplemented by pad printing solutions for adding the information necessary for the optician. Nevertheless the downsides of the well known pad printing technology are its limited flexibility, high costs for clichés and high maintenance. Currently, optical measurements of lenses using this equipment are limited to discrete positions on the lens, so there is no possibility to make a complete evaluation of a free form lens.

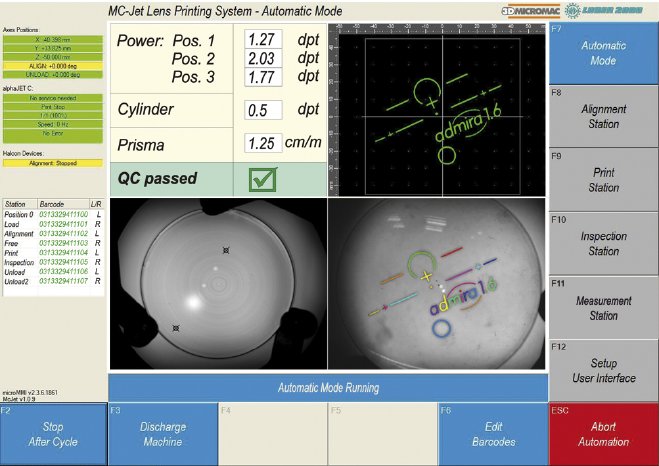

The MQ-JET 01 represents a new generation of measurement and control system combining ink jet printing with automatic lens mapping over the entire surface. This totally non-contact approach captures and records vital data such as optical power, cylinder and prism values, instantaneously.

The intuitive software allows the user to interrogate the power measurements at every point of the surface, using the XY coordinates and the diameter around these coordinates. Furthermore, the customer can define near and far field size of the measuring area, and the number of measuring areas for every lens.

The MQ-JET 01 accepts all lens types from single vision lenses with a central measurement point to progressive lenses with near and far field. Even special lenses with more than two fields of view (e.g. special glasses for pilots) can accommodated. In addition, the actual measurement values can be compared with the model data of the lens. Tolerance limits and levels can be set such that deviations from the optimal values of the lens will be shown in different colours e.g. green, red, yellow, for a quick visual comparison.

After mapping, the optical parameters of a free form lens can be detected. Only with these steps it is possible to make a complete quality assessment with the decision whether the lens fulfils the high quality standards of the manufacturer or not. The exchange of data accomplished via OMA interface. Customer-specific solutions are available that include a connection to an SQL data base to ensure statistical process control.

The MQ-JET’s acclaimed ink jet marking technology combined with these latest advancements make it strategically important and cost effective tool for manufacturers of high quality ophthalmic lenses.