The near-Lambertian properties of Spectralon and Spectraflect deliver a uniform dispersion of light that integrates light and reduces hotspots better than other materials in coated cavity applications. A high reflectance over a broad spectral range of 250-2500 nm increases optical efficiency. With increased efficiency, less light input is required for performance, lowering energy and design costs. Since light collection and reflectance are not dependent on the geometry of light input, design flexibility is increased. Inert, thermally stable and UV-resistant, Labsphere’s materials ensure consistent optical stability and long term performance reliability.

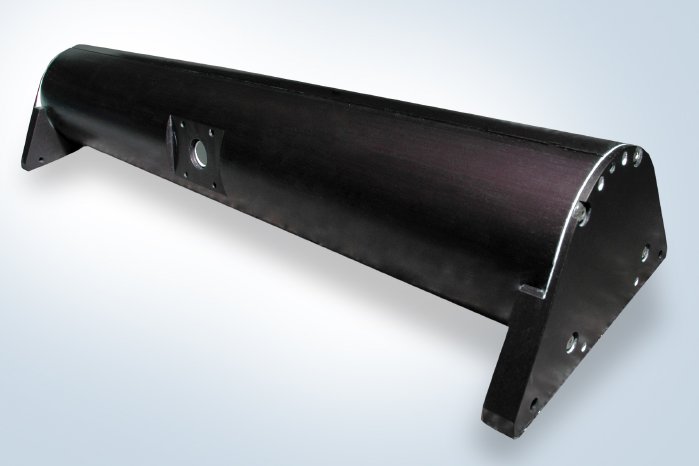

Machined Spectralon can be economically fabricated into a wide variety of shapes to meet many imaging instrument designs. In-house machining allows samples to be created quickly and easily, and modified throughout the design, prototyping and testing process. For other applications, Spectraflect diffuse reflectance material can be uniformly spray-coated on customer provided substrates.

About Labsphere:

Part of the global Halma group of technology companies, Labsphere is a world leader in light testing and measurement, and diffuse optical coatings. The company’s products include LED, laser and traditional light source light measurement systems; uniform light sources for imaging device calibration; spectroscopy accessories; and high diffuse reflectance materials and coatings for applications in backlit panel displays, computed radiography, and system calibration. Their expertise has resulted in multiple patents in areas such as methods for testing LEDs on a wafer and UV transmittance.