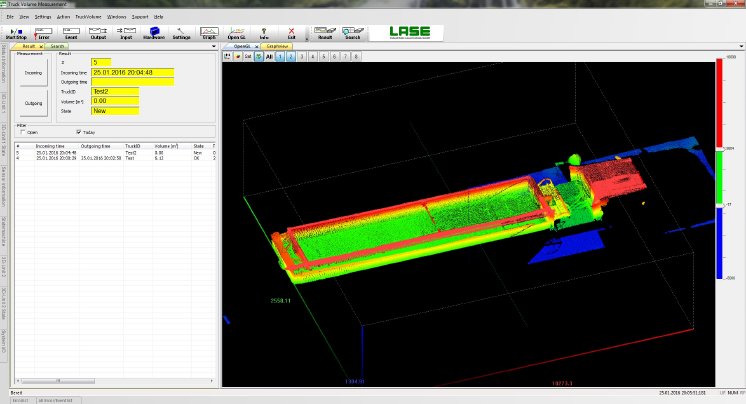

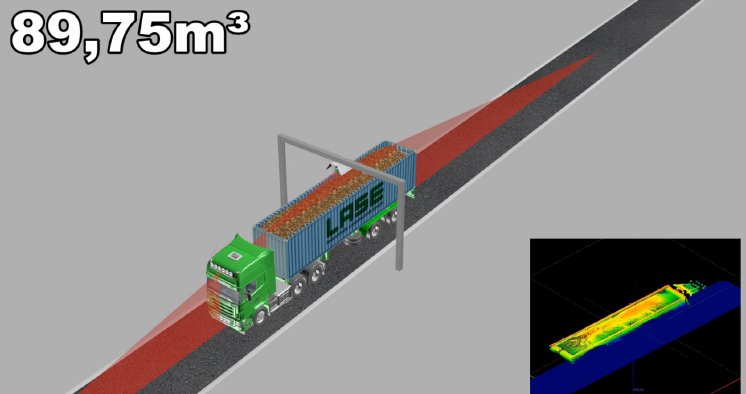

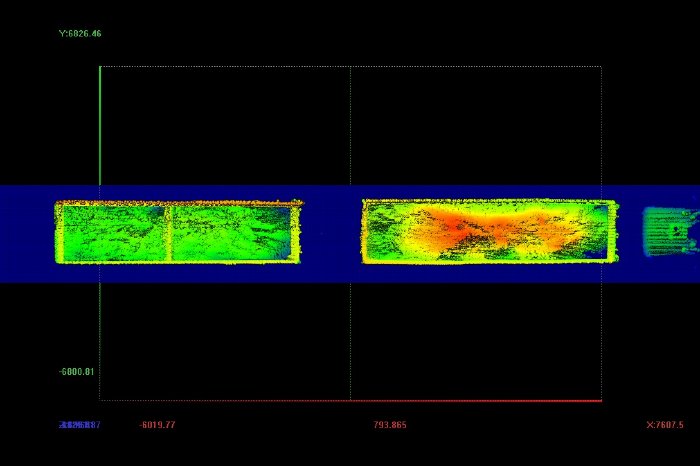

The application LaseTVM - Truck Volume Measurement is a highly precise three-dimensional measurement system especially developed for measurements of truck loading volumes. Two 3D laser scanners from the LASE 3000D-C1-11x series are installed over the entry of the loading area and measure the volume of trucks, which drive into and out of the plant. After arriving, the trucks have to stop under this 3D measurement system in order to determine the volume of the empty trailer. After being loaded with bulk material, the trucks have to stop again under the 3D laser scanners in order to determine the fully loaded trailer as well.

It also doesn't matter if the trucks have a single or double trailer. Both volume measurements (empty and full) are forwarded to the application software LaseTVM, which operates with specific software algorithms. The differential value out of the current loading quantity and the empty profile amounts to the loading volume. The 3D laser scanners are installed in a height of 5,50 m and in a distance of 8,00 m to each other - wide enough to cover the whole truck-trailer length with their scan planes.

Further system functionalities in this implementation are the recognition of the correct truck position within the 3D laser measurement area with light signals, data reception from license plate recognition and empty truck photographs, too. Due to system implementation in winter time, it was able to proof its robustness under rugged outdoor conditions immediately!

The application has a high versatility and can be used for volume and profile measurements of all different materials - such as ore, stones, sand or even wood chips - which are transported as bulk material on trucks. It eliminates faulty weight measurements by e.g. humidity within conversion (up to 20% of the volume) and can exclude weight manipulations. This highly exact laser measurement system has an accuracy of approx. 2% and ensures a comfortable resource planning for the customer.

Find out more on our product site...