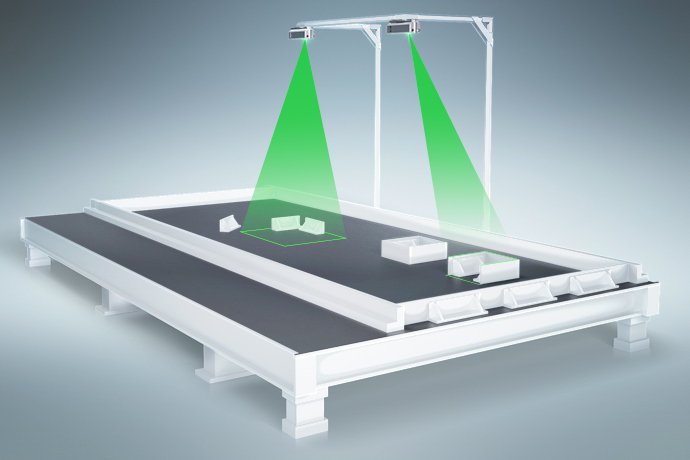

Laser projection systems for precast concrete parts production

Precast concrete parts factories must produce large quantities of the same quality in an ever-shorter time. At the same time, complexity of the produced parts is constantly on the rise. In order to face the ever growing complexity and meet the demand for high component quality and cycle times, more and more plants worldwide are implementing laser projection systems. These systems eliminate the need for manual measuring by means of a tape measure and optimize efficiency throughout the entire production cycle. LAP, a manufacturer of laser projection systems with years of experience in precast concrete parts production, will give a live demonstration of the system's functionalities. You will see step by step how to use the system for displaying cut-outs, formwork parts, mounting elements and conducting final check. Join us and learn how to minimize errors and optimize output of your production!

Key topics

- Live demo: how to use LAP’s CAD-PRO laser systems to accelerate manual set-up of pallets and tables, flat beds, or decks

• Control all processing steps with LAP’s PRO-SOFT operating software - From CAD data to laser projection – support for various data formats (Unitechnik, DXF, plotter formats, etc.) and master computer systems

- From mounting and installation to system configuration

The presenter

Max Mandt-Merck started his career with LAP in 2009. As sales manager for CAD-PRO laser projection systems, he has been responsible for the worldwide business activities in the precast concrete industry since 2014. That long-term expertise has given him in-depth know-how in concrete applications and profound knowledge in laser projection systems.

Dates

To respect our partners and customers worldwide, we offer different dates and times. Interested companies worldwide can attend the webinar live in their specific time zones:

EMEA

Tuesday, May 26, 2020 •09:30am CEST (webinar will be held in German)

Tuesday, May 26, 2020 •11:00am CEST (webinar will be held in English)

USA

Tuesday, June 9, 2020 • 08:00pm CEST (webinar will be held in English)

APAC

Wednesday, June 10, 2020 • 08:00am CEST (webinar will be held in English)

Registration

For further information and registration, please click here.

Unable to attend the live webinar? Please register anyway. The webinar will be recorded and available to view at your convenience. Attendance is free of charge.

For further information, please visit www.lap-laser.com. Follow us also on LinkedIn