"As a specialist in fine ceramics, Kyocera customdeveloped these vacuum chambers in close collaboration with CERN for the LHC's unique requirements," says Mitsuru Imanaka, the President of Kyocera in Europe.

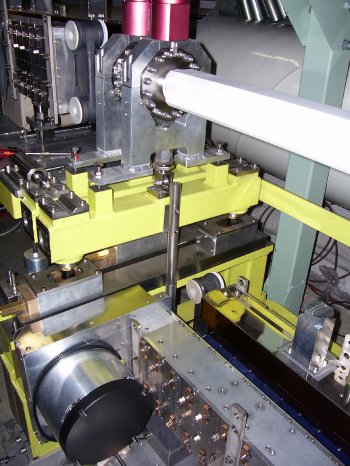

The vacuum chambers work in a way similar to railway switching points, guiding protons through the largest machine in the world. When necessary, protons can also be removed from the LHC by rapidly alternating magnetic fields - for example, when the LHC is to be shut down. The chambers are made of fine ceramic because metal would produce a time lag in the magnetic fields that drive the protons. Kyocera's chambers maintain the vacuum state present in the whole LHC system in order to keep the racing particles from hitting air molecules, which would otherwise reduce the protons' speed or alter their precisely controlled direction.

Kyocera was the only company in a position to meet CERN's exacting specifications for the vacuum chambers. "The technical demands of making a fine ceramic component increase in direct proportion to its size and shape," Imanaka explained. "These vacuum chambers exceed one meter in length, requiring us to maintain a uniform, homogenous structure over a large area. Kyocera's material and processing expertise have allowed us to produce fine ceramic components to overcome technical challenges at CERN and in many other industrial and research applications."

The LHC showcases the unique properties of Kyocera's precisely refined ceramic materials. Ceramic serves as an electrical insulator, allowing particles to be freely manipulated in the LHC's highly electromagnetic environment. In addition, ceramic is more resistant to extreme temperatures, friction and corrosion than other materials - critical attributes for such a worldleading scientific project.

While the LHC is the world's largest particle accelerator, Kyocera's precision ceramic vacuum chambers are also utilized in smaller accelerators at national laboratories and universities in the U.S.