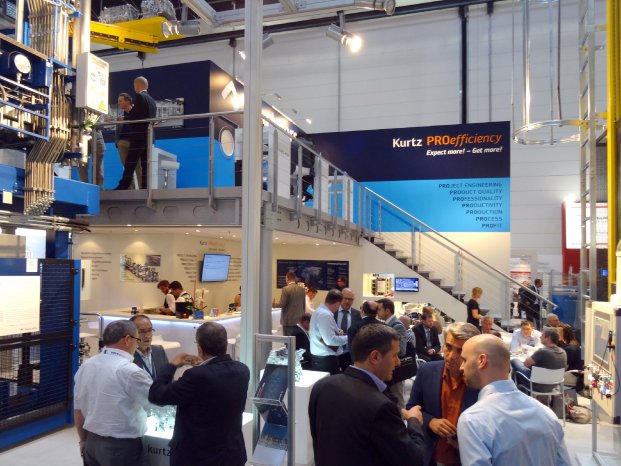

The interval between the last GIFA and this year’s event was around 48 months and a lot had happened in the foundry world in the meantime. The team at Kurtz foundry machines had quadrupled its sales in those four years, and made perfect use of the time to further develop the high-performance technologies and solutions in low-pressure die casting for enhancing customers’ productivity and efficiency. With the motto Kurtz PROefficiency: Expect more! – Get more! the system supplier for foundry equipment showed just what is possible in low-pressure die casting. With two enormous machines – a 40-tonne, 9-meter low-pressure casting machine and a 45-tonne trimming press with a height of 7.5 meters and a press force of 300 tonnes – Kurtz GmbH delivered an impressive fair exhibition which presented an enormous logistic challenge even before the event. In addition, a two-storey fair stand was built which allowed existing and potential customers to examine the machines up close. But not only was the size of the systems at GIFA impressive, the capabilities of the technology also convinced the public. One example from the automotive world: The AZ 80 casting machine used the self-confident slogan “1 shot – 2 engine blocks” for doubling productivity by means of multiple assignment, making the production of two crankcases possible per cast. The parts moulded on the machine are used in numerous vehicles by well-known automobile manufacturers. A further main attraction was the powerful trimming press KPS 3000 which, with its fast-moving bulk, soon became a crowd-puller for enthusiastic visitors in the live demonstration. Also technically impressive: With a large sliding-tilting table, it permits the efficient hydraulic flash removal from large moulded parts at a remarkable speed. A wide range of options and customer-specific adaptations make tailored solutions possible for the greatest cost effectiveness. Visitors were impressed by the performance capacity of low-pressure die casting which has become a genuine alternative to pressure die casting. Just a few years ago, even the experts would not have anticipated this of low-pressure die casting.

Productivity increase in top quality

Anyone aiming to produce parts of the highest quality at the lowest possible cost is constantly aware of the topics of “productivity” and “efficiency” – whether in the planning phase or directly in production. This was one of the central topics at the Kurtz fair stand. As well as in everyday business, the system supplier Kurtz supports its customers and potential customers with soundly-based knowledge such as advice in the technical design for casting and trimming the parts and the selection of the ideal casting method in terms of processes and machine engineering. Lothar Hartmann, Sales Director at Kurtz Gießereimaschinen was delighted with the successful participation in GIFA 2015, which generated numerous inquiries and finalised sales, and foresees enormous growth opportunities for the foundry equipment segment: “With Kurtz’ engineering competence in automation and logistics solutions, competitive advantages can be achieved which really pay off and increase earnings on a sustainable basis – whether with stand-alone solutions or a complex, fully-automated casting ladle, automated core and moulded parts handling or with robot-assisted tilt casting with servo-hydraulic regulated casting machines. Our product portfolio is tailored directly to the requirements of our customers and can be perfectly adapted to individual needs – this is something our customers know and value.