Since Euro 5 and Tier 4i, Pierburg has been series manufacturing high-precision motorized BPVs. The Company is the only single-source supplier of complete flap and actuator systems. Commercial vehicle service-life requirements of up to 1.6 million kilometers or 20,000 operating hours can be met using the newly developed modular system with a variety of actuators. The system is suitable for all types of vehicle, from light- through medium- up to heavy-duty.

A wide variety of applications

NOx emissions are nowadays reliably reduced with the aid of modern technologies: by systematic exhaust-gas recirculation (EGR), by SCR systems, or by a combination of the two. In each case, a back-pressure valve is recommended. Featuring further functions, the valve can be combined to form a low-cost system and thus fulfill such tasks as assisting in EGR or thermal management for SCR and diesel particle filter regeneration. Other functions include engine-assisted braking for reduced wear on the primary brake system, or gear-shift assistance for automatic transmissions.

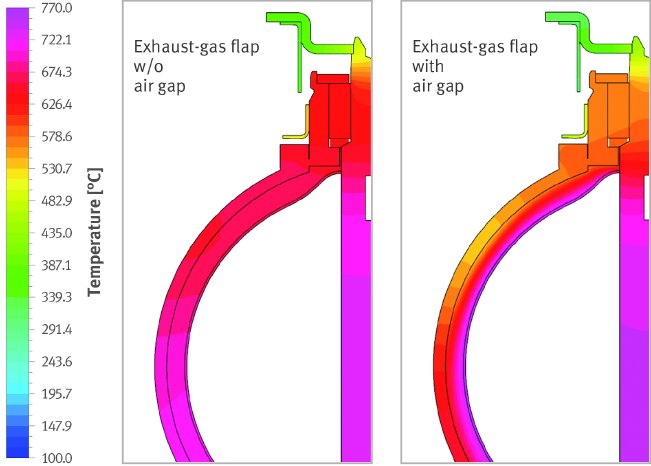

Double-wall design

With a view to continuously rising technical requirements, the newest product generation has a double-wall welded housing for protecting the actuators and neighboring components from overheating. This reduces the cost of the more expensive option of thermal insulation to a minimum. New high-temperature resistant bearings take account of the general rise in gas temperature.