The broad application knowhow of the KOMET GROUP with regard to special milling processes for the inner and outer machining of sophisticated components is reflected in the performance of the new JEL® PCD face milling and screwin cutters. JEL® PCD face milling cutters are monoblock tools with an HSK-A63 adaptor. The increased number of flutes in relation to their diameter is particularly impressive. For example, tools with a diameter of 40 mm have 10 cutting edges and tools with a diameter of 125 mm have 22. In conjunction with the stable design of the solid basic body, this enables short running times with high milling feed and infeed rates along with the best possible tool life. The solderedin cutting edges enable cutting depths of up to 8 mm. One of the advantages of brazed cutting edges that is appreciated by users is that there is no need to adjust the tools. Users can connect to the new KOMET SERVICE® network to have their tools repeatedly precision retipped by selected service partners. If desired, such tools can be delivered immediately through our exchange service.

JEL® PCD face milling cutters are available in diameter ranges of 40 to 160 mm and in two designs, with eroded and specially treated cutting edges and advanced cutting edge geometry. They can achieve surface roughnesses of < Rz 10 µm to meet extremely high surface quality requirements. With fine balancing and very tight production tolerances, surface qualities of < Rz 5 µm can even be achieved. This makes the new JEL® PCD face milling cutters ideal for face milling processes for the semi- and finish machining of lightweight construction materials such as cast or solid aluminium, magnesium and fibrereinforced plastics. The rotational speeds are 20,000 rpm and the maximum cutting speeds are around 5000 m/min. Feed rates of up to 0.3 mm/flute can be achieved, depending on the material to be machined, the selected cutting depths, the required surface quality, the clamping parameters, and the stability of the machine.

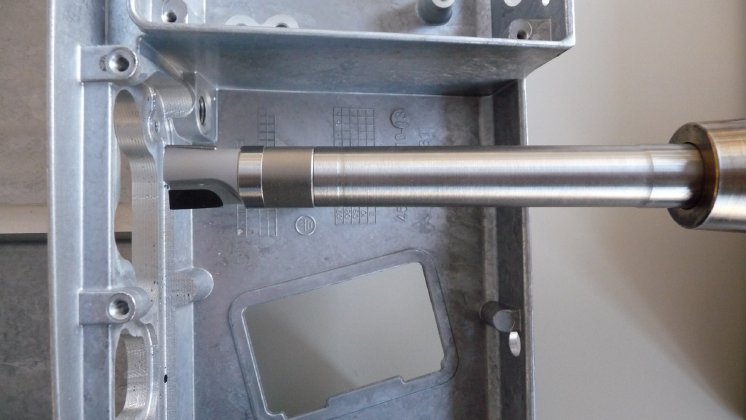

The second new standard range of milling cutters comprises the JEL® PCD screwin milling cutters. These modular systems, which are unique in their tooling sector, are extremely flexible and easy to use. This is mainly due to their easily changeable milling heads. The milling systems consist of a shrinkfit holder, an extension, and a changeable screwin head. Five different extensions are available. For the short variant of the tool, the heads are made of steel and for the long variant they are made of vibrationdamped heavy metal. Thanks to the front clamping of the changeable heads, the heads can be quickly and easily replaced directly in the machine without needing to remove the tool shank or make any further adjustments to the cutting edge. By customising the flexible tools using exchangeable components, you can carry out diverse milling operations. This means that JEL® PCD screwin milling cutters with their modular cutoff area can be used costeffectively in series production as well as for prototype and preseries production. They reduce costs and mean that fewer tools are required because they can be set to different lengths.

The face milling variant of the new standard screwin cutter is available in diameter ranges from 10 to 32 mm. The routing cutter variant is available in diameter ranges from 10 to 25 mm. They can be used for face milling, slot milling, peripheral milling, and circular interpolation milling in the premachining and finishing of aluminium components and in machining shoulders and grooves. They also solve problems involving long projections.

The new JEL® PCD face milling and screwin milling cutter ranges enhance the standard cutting tool range of the KOMET GROUP for machining lightweight construction materials. This unique and extremely wide range of PCD tools enables customer requirements to be met quickly and flexibly. The product range encompasses the brands KOMET®, DIHART®, and JEL® and contains tools ranging from highperformance PCD drills (spiral design or fluted), PCD routing cutters, and PCDequipped thread mills to PCDequipped reaming tools.