"Recognizing the industry's need for high versatility, ever greater efficiency, and reliability without compromise, we designed these machines to expand on the capabilities of our other machines - which themselves are highly capable and proven," said Jeff Vogel, Vice President Engineering & Production at Pemco.

Model 33 Ream Wrapper - A flexible quick-change artist

The Model 33 wraps a wide variation of product sizes from the smallest B5 Japanese sizes to larger GTO sizes such as 364 mm x 520 mm (14.33" x 20.5"). Like Pemco's other ream wrappers, the Model 33 offers both kraft and polypropylene wrapping capability.

Servo technology helps speed size changeovers. This approach has already been well proven in Pemco's Model 39S high speed wrapper. In the Model 33, size changes are further facilitated by attributes such as fewer size change parts and optional motorization. The optional semi-automatic size change function uses preset recipes loaded by the operator, for changeover times of 10 minutes or less.

The Model 33's new polypropylene heat seal unit has individual heater controls, ensuring tight tolerances for consistent temperature control. This capability is especially important for versatility as wrapping materials continue to evolve.

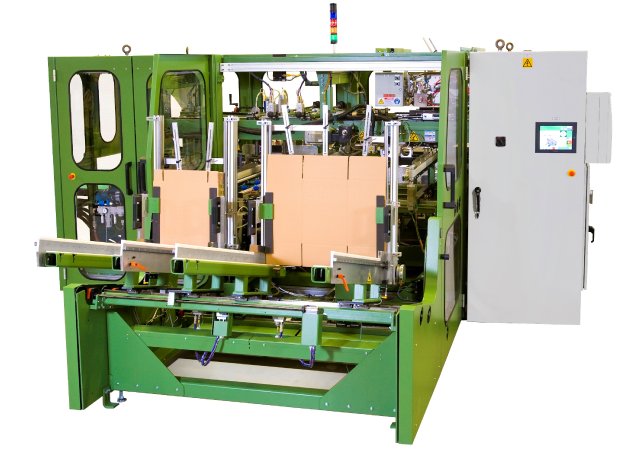

Model 163 Case Packer/Lidder - Small, versatile, and highly precise

The Model 163 case packer/lidder also incorporates Pemco's servo technology, along with an array of new technologies in a revolutionary design. Its small footprint makes it an ideal replacement for existing case packer/lidder units.

Like the Model 33 ream wrapper, the Model 163 case packer can process cut-size reams ranging from the smallest B5 Japanese sizes to the same range of large GTO sizes. It, too, incorporates new size-change features (no change parts and optional motorization) for change times of 10 minutes or less.

During operation, timing belts provide precise transport and positioning for carton and lid folding, and spring-loaded blank hold-down mechanisms simplify blank loading. Blanks are positively driven by flight fingers, ensuring correct, consistent placement for each ensuing ream stack.

The Model 163 case packer/lidder is offered as a straight-through or side-infeed machine. Customers can choose between two-piece (case & Lid), wrap around case style, or both.

Pemco Inc.

Pemco is a manufacturer of complete packaging lines for cut-size and folio-size paper and board, SHM brand folio-size sheeting systems for paper and board, and specialty stationery packaging machines for envelope filling and sealing. The cut-size paper packaging equipment includes wrappers, labelers, stacker-accumulators, case packers and lidders. Pemco also represents the Wrapmatic brand.

Pemco is part of Körber PaperLink, a system supplier of premium solutions for the paper and tissue industries.