Dedicated requirements of the folding carton industry

With the newly developed automatic splice and the high-speed automatic pallet change features, the SHM 1450 / 1650 DR sheeters are the answer to the demands set in today's folding carton printers and converters. "The folding carton industry continually requires new product design formats," said Wolfgang Faust, Vice President Sales at Pemco. "Consequently, folding carton converters and commercial printers need to deal with a variety of products converted to an unlimited range of sheet sizes. Without an in-house sheeting solution a large inventory of sheeted products must be purchased."

More than ever, commercial printers are looking for their own in-house sheeting solution, especially when Just-in-Time delivery is unavailable. This significantly reduces lost time, procurement and inventory costs.

For board converting, the SHM sheeter is available in working widths of 1450 mm and 1650 mm, which supports the maximum capabilities of the customer's printing equipment. For most printers, the SHM 1450 / 1650 DR sheeters allow for a maximum five-pocket operation, maximizing printer efficiency.

New developments for efficient converting of board:

Automatic splicing...

The SHM 1450 / 1650 DR sheeters are equipped with an automatic splice to reduce reel change times when converting board. "The average running time of a board reel on a high-speed sheeter is 15 minutes," explained Wolfgang Faust. "After that the reels need to be changed, which takes approximately 5 minutes. This translates into a potential six hours of cost savings per day." Pemco offers two versions of the automatic splice: splicing at speeds of 150 m/min or 300 m/min. The latest version carries out the splice with minimal or no production speed reduction.

No waste high-speed pallet change

The second improvement for higher efficiency in board sheeting is the high-speed automatic pallet change. With no wasted product, it will perform at speeds up to 300 m/min with limited reduction in production speed. While the full pallet is discharged and the empty pallet is inserted, the sheets accumulate on a retractable table. Other solutions usually waste a minimum of three sheets per pallet change, which easily adds up to 158,000 sheets per year.

Optimized sheeting production: versatility, quality, capacity

The SHM 1450 DR utilizes a maximum cross cut of up to 57 inches (1450 mm) wide, while the SHM 1650 DR has an increased cross cut of up to 65 inches (1650 mm) wide, both with a tolerance of ± 0.015" (± 0.381 mm). With a knife load for the cross cutting head of up to 1000 gsm and 600 gsm at the slitter stations, the dual rotary system handles significantly more capacity with greater accuracy than a single rotary system. The maximum running speed of the machine is 350 m/min.

The cross-cut knife system is a state-of-the-art 'synchro' cutting head producing superior cut quality and a high profile speed curve. This provides customers with more flexibility to handle the full range of lightweight fine paper up to a variety of paperboard. It is manufactured for Pemco by its sister company E.C.H. Will assuring the highest cut quality and accuracy levels in the industry.

When running heavy, high quality coated product on sheet-fed printing equipment, product quality is a priority. The SHM 1450 / 1650 DR sheeters are designed to cut almost any type of board provided in the market with precision sheet length, cut quality and cleanliness. The folio sheeter delivers sheeted products as press-ready stacks. The top-quality cut practically eliminates dust, which may otherwise be problematic for the printing equipment.

According to Wolfgang Faust, "Due to its advanced automation concept, the sheeter can provide up to 50 % more output, even with a variety of products. Going from one product to the other requires minimal set-up time and can often be completed in just a few minutes."

Proven technology in operation

Visitors to the PRINT 09 show, taking place September 11 to 16, 2009 in Chicago, IL, can learn more about this solution at Booth 3600, hall B1 and can arrange for a visit to the Pemco Open House in Sheboygan, WI. There, the SHM 1650 DR, equipped with auto splice and high-speed automatic pallet change will be demonstrated, including simulated production runs, for the duration of the exhibition.

Pemco Inc.

Pemco is a manufacturer of complete packaging lines for cut-size and folio-size paper and board, SHM brand folio-size sheeting systems for paper and board, and specialty stationery packaging machines for envelope filling and sealing. The cut-size paper packaging equipment includes wrappers, labelers, stacker-accumulators, case packers and lidders. Pemco also represents the Wrapmatic brand.

Pemco is part of Körber PaperLink, a system supplier of premium solutions for the paper and tissue industries.

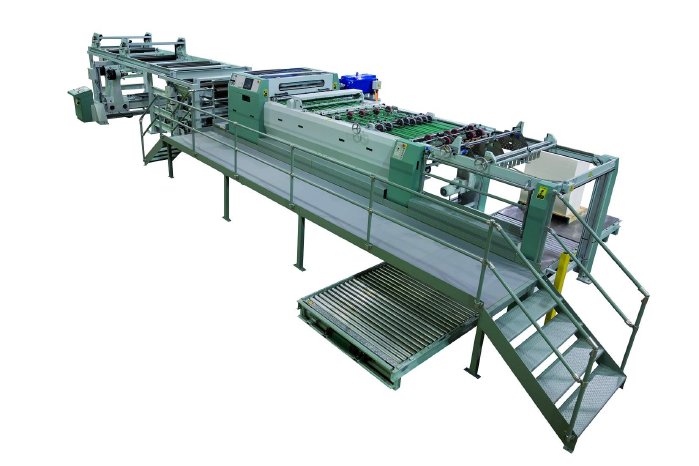

Photo 1: With the high-precision folio-size sheeter SHM 1650 DR, sheet output per day is often tripled when combining the decrease in waste and incorporating automatic splice and high-speed automatic pallet change.