In many companies around the world, these five innovative offset keyless inking units with UV curing have long since established themselves as a permanent fixture in printing works and specialist companies in the plastic and paper-printing industry. Even screen and digital printing works have long since had to face the hard fact that the economic aspects of their investment goods are crucial contributory factors to the success of the company. This compact and flexible UV printing press has enabled companies to open up whole new business segments. "Waterless and keyless" is the name of the innovation that is helping more than just niche market printers achieve success.

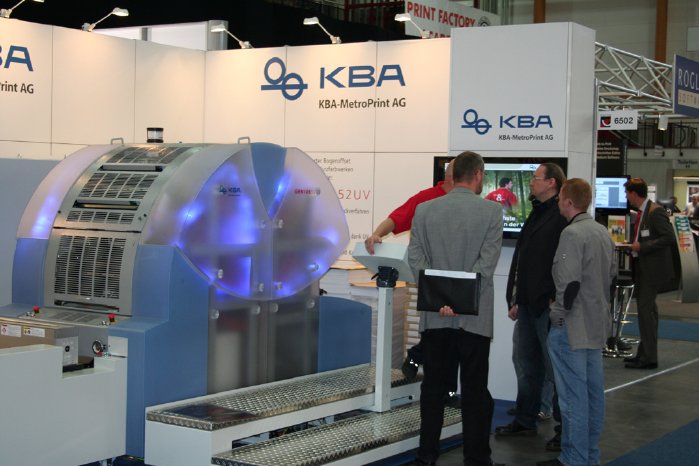

"The high-quality printing results mean the Genius 52UV is still currently unrivalled on the market. Smears are no longer par for the course and customers achieve the quality they are used to from conventional offset printing and more. Screen and digital printing is still struggling to keep up", explained Antonio Morata, Marketing Manager, KBA-MetroPrint AG.

In terms of wastage and the ability to dispense with solvents in offset, the Genius 52UV is both unique and environmentally friendly. The press offers extremely fast inking up and, thanks to the five waterless and keyless inking units, excellent run-length stability. The UV dryer enables instant further processing after printing, even on difficult materials, such as PVC, ABS, PS and other plastics, as well as coated paper and board in a substrate thickness of 80gr. up to 0.8 mm. And the unique inking unit technology and absolute register stability, as a result of the single gripper action, means there is no ghosting.

"Our customers report that production runs as small as 300 sheets are already economically viable in comparison to digital printing. It is the wide range of applicable substrates and finishing types that make this press so attractive to so many users", concluded Morata.

Further information:

www.kba-metroprint.com

www.druckform-messe.de