The coding systems of KBA-Metronic have a common ground: they are simple in the operation, flexible in the application and extremely reliable in the production.

Sets standards: the alphaJET evo

The ink-jet printer alphaJET evo is a new development, completely orientated at the needs of the market. The freely programmable system bases on the continuous ink jet principle like its predecessor, marking contactless onto most different surfaces individually. The alphaJET evo disposes all current interfaces, such as Ethernet, USB, RS232 etc. which allow smooth integration into new or existing production processes. The alphaJET evo convinces with a robust stainless steel housing and the safety class IP 65 for advanced environmental conditions. The solvent recovery unit is standard equipment in the economical (thrifty) alphaJET evo.

The 10.4" TFT color display leads the operator simply and intuitively through the CE Windows supported operating system. Because the tough touch panel is slewable and removable, it can freely and easily accessibly be placed.

The unique ability of the alphaJET evo to print True type for fonts without speed loss is very much of value to everyone who attaches importance to an attractive packing design. Thanks to this ability, logo editor and embedded graphics programs are redundant. Logos and graphics can be e.g. created with a PC graphics program and transferred as a bitmap to the ink jet printer.

Power packages are the coding laser systems of KBA-Metronic

The economical and compact laser system iCON i-1010 is ideal for small character coding applications for packaging, packed and industrial goods and offers users an favorable alternative. .

Thanks to their compact (slimline) design with an integrated control unit, the laser systems of KBA-Metronic are uncomplicatedly integrateable to almost every production line. With continuous and intermediate operation both stationary and moving products can be marked permanently and tamper-proof. The laser system is a reliable and environmentally friendly solution without additional consumption.. It is ideally for permanent and cost effective coding of cardboard boxes, ceramic, wood and glass, metal, synthetic materials and paper.

Both standard coding applications like sell-by dates or batch numbers and complex applications like graphics, logos, bar codes and data matrix codes, are possible. Whereupon for the marking of particularly thin materials, special fonts as Crystal Font, are available. Even the high requirements of the pharmaceutics (21 CFR part 11) can be fulfilled. Besides the interface protocol RS 232 for the most laser systems, an Ethernet journal (log) which permits the simple integration into existing networks as well as the connection to merchandise management systems (ERP) is available .

With many years of experience KBA-Metronic offers air-cooled CO2, Yag and fiber lasers which work without external compressed air or water for cooling.

"State of the art" with laser markable labels

In cooperation with Herma KBA-Metronic presents the unique system solution for the economic and safe coding with laser markable labels.

Exactly coordinated with each other, the two systems - the labeller H400 and the CO2 laser K-1000 - convince with attributes like speed, process reliability and economy. Work areas of 250 x 250 mm can be realized in the move or in the standstill.

Opposed to other technologies the coding system for laser markable labels works contactless. Because laser systems work without consumables, additional costs and holding times in the production resulting from it are dropped. If the laser is installed directly over the rigid beak, the last lable can be marked and used. This is ideal for the internal logistics and the shipping marks of cartons, shipping boxes and pallets.

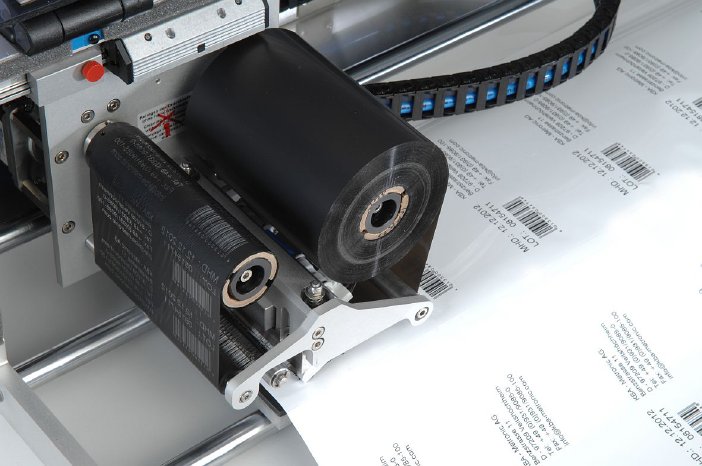

The thermal transfer printer ttPRINT is a flexible all-rounder

The ttPRINT is a continuous and intermittend direct print module and is for the installation into horizontal and vertical packing machines suitably to indicate packaging and products freely programmably and in a high print resolution. By the separate control unit and the possibility of choosing between a right and left print head version the ttPRINT can easy be integrated without problems.

Another advantage is the efficiency of the ttPRINT cassette system. It takes up to 900 m of thermal transfer foil, so that the number of foil changes and with that the downtimes are reduced considerably. Moreover, another handsome cost reduction is by the transfer ribbon optimization: the print head lifts as of this automatically at areas which shall not be printed. Ribbon is saved by it and lasts longer. Extensive printing areas or many little products in multi-web packing machines can be marked with the ttPRINT Multiline efficiently for themselves. With three standard print head width (53, 107 and 128 mm, and an ttPRINT control unit with safety class IP65 - a ttPRINT can be adapted to the individual requirements.

Hot: hpdSYSTEM vario and nano

The robust and reliably working hotstampers have their solid place in the industry. New are the user friendly units vario and nano of KBA-Metronic with speeds up to 1,000 times/min. without compare and replace the M-series off. hpdSYSTEM contains the smallest on the market available hotstamper size and the easy operable cassette system. Galleys (type holders) and types are all-purpose. Our in-house engraving studio manufactures stamping clichés from brass, steel or magnesium following customers individual demand, coordinated with the respective intended purpose especially.

The feeding system udaFORMAXX for maximum independence

With the redevelopment of the feeding system udaFORMAXX the coding of material cuttings and folding boxes up to 450 mm x 500 mm - also with automatic folding - outside the production line becomes a mere child's play. With only a few hand grips different formats and material thicknesses up to 8 mm can be feeded. The intuitive Touch panel stands for a maximum amount of using comfort and is per default multilingual. An extended work area is reached with the pressure point justification by means of a light barrier. The udaFORMAXX can modular be deduced with most different marking and coding technologies and reading systems to have a stand-alone-solution that can exact and precisely print the individual marking of folding carton & Co. with speeds of up to 90 m/min .