InspectionXpert OnDemand: From PDF / CAD drawing to inspection packages in minutes

"Time-consuming and error-prone manual ballooning can thus be eliminated, and the transfer of measurement results into inspection reports will then be a thing of the past".

As the CEO of K2D-KeyToData GmbH, Jochen Layer, emphasizes, the latest versions of InspectionXpert OnDemand "allow even faster creations of, for example, first article inspection reports". With the inspection planning software InspectionXpert, drawings and models can be ballooned digitally with just one simple click and create professional and complete inspection compliance reports in an automated way.

Features are captured automatically and transferred to inspection report templates (customer-specific or according to standards like FAI, PPAP, AS9102, etc....). "This means that routine work for inspectors or employees involved in this process, it is less tedious and can save up to 90% on standard timescales.

The highlight of InspectionXpert is the easily ballooning of PDF drawings - even scanned drawings can be used. The Optical Character Recognition (OCR) can be used to capture characteristics and associated tolerance values in a simple manner. Here our customers achieve the biggest time savings," emphasizes Layer. "Our customers often print out PDF drawings, ballooning them from hand, then transferring the measurement results manually. This is really no longer necessary.”

"InspectionXpert also supports CAD file formats without the need for a CAD license. This includes AutoCAD DWG 2D, CATIA V5 / V6 2D + 3D, Creo / Pro/Engineer 2D + 3D and Siemens NX 2D. "It is self-evident," says Layer, "that it is no problem for InspectionXpert, to import measurement results from measuring instruments combined with an automatic comparison with the special requirements.”

Furthermore, InspectionXpert can be combined with many software solutions which are a standard for quality assurance such as Verisurf, Net-Inspect, QDM Quality Management System, CEBOS MQ1, Prolink's QC Gage and many more. Various customers also use InspectionXpert with SAP!

Subscription Software: InspectionXpert OnDemand

With different versions of InspectionXpert OnDemand, K2D-KeyToData is meeting "numerous customer requests". This version of the QS software is launched via a web browser and is "available without installation, anytime, from anywhere in the world," emphasizes Layer. “Nobody must look after updates; the software is always automatically up-to-date". InspectionXpert has recently also been available - besides German and English - in an Italian language version.

A Powerful combination: InspectionXpert OnDemand and the software innovation QualityXpert

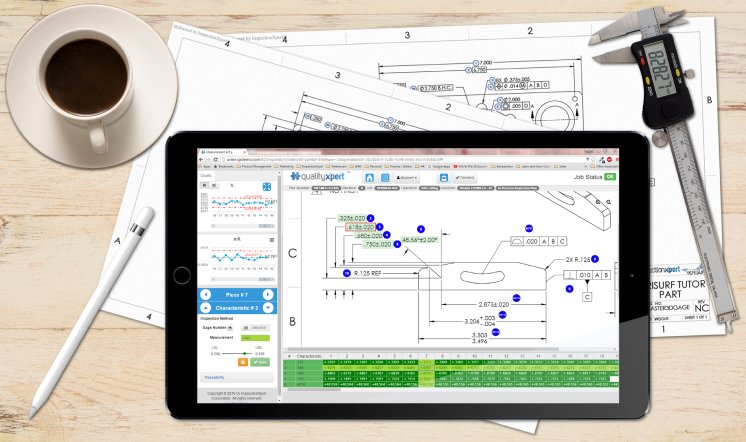

A combination of the software solutions InspectionXpert OnDemand and the brand-new QualityXpert enables companies to work paperless from the inspection drawing to the inspection report and process analytics. Processes are continuously optimized and still the highest manufacturing quality can be reached. “Automatically generated ballooned drawings and inspection plans become self-evident". InspectionXpert OnDemand automatically generates these from PDF drawings as well as native 2D & 3D CAD data. - "The created inspection plans can then be transferred seamlessly to QualityXpert", says Layer.

QualityXpert: Optimized quality control in real-time

“That is my absolute highlight on the Control 2017”, Layer designated the software solution "QualityXpert". The goal of the developers was "to create an innovative, web-based platform for PCs and tablets designed for the manufacturing environment, which combines all essential areas of quality control and optimization of quality processes". With this innovation, says Layer, it was possible to reduce time and costs in production while at the same time improving the product quality. According to Layer, workers on the shopfloor and quality inspectors can record measurement results in in real time for analysis.

QualityXpert combines all essential areas of quality control and optimization of quality processes:

- Data collection and evaluation: Efficient monitoring of critical manufacturing processes for qualified decisions are based on precise and empirically collected data.

- Statistical Process Control (SPC) in real-time: predictive management of alerts, identification of deviations and the reduction of rejects. Avoiding inefficient "overprovisioning" and process capability studies.

- Production-Release-Procedure (PPAP): Preparation of required documents such as the investigation of process capability, process flow diagrams, process FMEA, analysis of measuring systems, production control plans and more.

- Test and measuring equipment management: Efficient management and monitoring of the necessary test and measuring equipment. Definition of calibration and test instructions. Gage R&R.

With the introduction of Verisurf 2017, the latest version of the company's measurement software comes to the European market, bringing the capability of advanced surface analysis, quality control and reverse engineering within a single soluton. The Verisurf User Interface (UI) has been redesigned; it is now fully equipped with new icons and extended "tooltips". Workflows are optimized, making applications easier and easier to learn, of course adapted to the latest Windows standards. After extremely fast 3D measurements from almost any CMM or portable device, Verisurf analyses the nominal CAD model and compares it against both internal and vendor inspection data. Stationary as well as mobile programming of measuring machines is self-evident.

Visitors of the Control can observe a modern 3D scanner presented by Verisurf at the exhibition stand. With the "Master3DGage" quality problems can be precisely determined and solved in real-time, rejects are reduced. "The productivity of each machine is thus increased," emphasizes David Olson, Director of Sales & Marketing of Verisurf. "Together with the K2D and InspectionXpert, we are continuously working on effective, seamlessly integrated and user-friendly solutions for quality assurance".

Control 2017: Powerful standalone solutions - perfect in combination

“Interested visitors will experience how complex processes in the quality inspection can be simplified with the software solutions of InspectionXpert and Verisurf and how the integration of the systems work together without problems. We are pleased to present solutions from InspectionXpert and Verisurf here on site by classic samples on computers as well as on a measuring machine, "says Jochen Layer. "We are proud again to be able to present together with QualityXpert an interesting development in quality assurance," says Jeff Cope, Managing Director of InspectionXpert. "QualityXpert is the world's first real-time quality inspection solution that enables workers on the shopfloor as well as quality inspectors to record test results in QualityXpert and make the results available in real time for analysis. -

Fabrication rejects? These belong to the past!"

The K2D-KeyToData will easily demonstrate to visitors the value of integrated solutions (ROI - Return on Investment) by using solutions of InspectionXpert.

"We would like to invite the visitors of the Control 2017 to get to know the CEO of InspectionXpert, Jeff Cope. He will stay with us in Hall 6, Stand 6204 and will be glad to answer questions about InspectionXpert OnDemand and QualityXpert. Visitors are invited to watch live demonstrations, how easy InspectionXpert allows you to work in a paperless environment from the inspection drawing to the inspection report – and this in minutes!”

In order to avoid waiting times, the K2D-KeyToData GmbH recommends to arrange appointments in advance. Simply choose a preferred appointment https://calendly.com/jochenlayer/control-2017, call +49 (7152) 94530 or send an e-mail to info@keytodata.com.

Specialist Lecture: 21st Century Productivity Quality Solutions

On May 12, 2017, from 12:20 - 13:30, an interesting lecture will take place in hall 7, booth no. 7526: "21st Century Productivity Quality Solutions. From Part Inspection to Quality Analytics and Compliance." Presented by: James Barnes, Verisurf Inc. and Jeff Cope, InspectionXpert Corp.