'Modern couplings have to meet a large number of different demands', explains Dr. Ing. Arno Wörn, engineer at JAKOB Antriebstechnik. 'First of all, they have to be light but at the same time extremely rigid as well as self-locking during the clamping process.' On top of that, they have to be monitored electrically and operation should be intuitive. Former systems used to opt for a hydraulic or electro-mechanic clamping solution. 'But especially in the event of retrofitting, these versions have adverse effects on economic efficiency', Dr. Wörn points out. As a general rule, it is advisable to use elements which are already available in the system to operate the automatic couplings. 'The hydraulic concept used to result in costly and complex maintenance needs.' After all, additional pumps and supply lines have to be installed. 'On the whole this solution costs a pretty penny.'

The scenario is quite different when electric motors are employed to operate the couplings. The electric drive adds a lot of weight to the coupling. 'The dependence on power becomes a problem during a blackout, though', explains the engineer. 'Due to the high gear ratio, releasing the coupling is difficult then.' Transfer rail couplings manufactured by JAKOB Antriebstechnik evade these disadvantages and thus guarantee highly dynamic transport and precise exchange of tools. The innovative systems are available for axial and vertical set-ups.

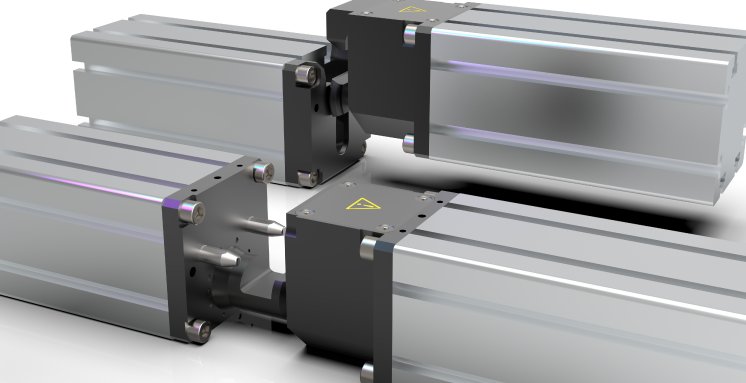

The types PKH and PKV can be adapted to all common profile rails. In addition to the pneumatic-automatic variant, there is also a manual-mechanical version of the clutch systems in the portfolio. These are fixed conventionally with a screw. 'The couplings themselves close five millimeters wide gap between active and passive parts independently,' says Dr. Wörn. The couplings are electrically interrogated. They can be installed either directly or via simple adapter plates. Power clutches can also be set up on the automatic systems. 'With the closing process, they make the electrical and the pneumatic connection to the exchange rail.' The advantages are obvious: the PKH-P and PKV-P pneumatic solutions are both light and hydraulic systems independent of power failures, but are low-maintenance and economical, as are couplings with electric drives. In operation, the gripper couplings ensure significantly shorter set-up times - and thus increase the productivity of the entire system.