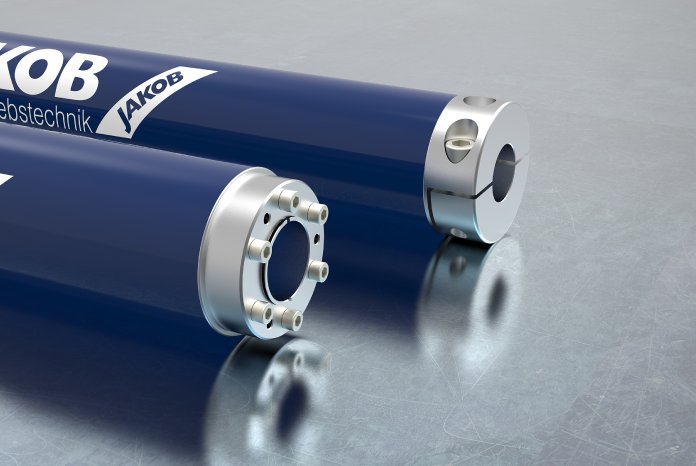

The main design feature of the distance couplings for large wheelbases is a variable-length intermediate pipe from aluminium, steel or carbon fibre composite (CFC), which can be optimally adapted to the customer's specific application. Inside the metal bellow, it is supported on the hub parts by a special Cardan bearing. This relieves the bellow element of the pipe weight and in the event of impact, the possibility of damage to the unit and physical injury is ruled out from the outset. The precision manufacture of the individual elements achieves high concentricity characteristics and quiet running behaviour. They are capable of transferring torques up to 3200 Nm and can be mounted to shafts with bore diameters of up to 100 mm.

The couplings are suitable for a host of applications as connecting, joint and synchronous shafts and replace intermediate shaft structures with complex, additional intermediate bearing arrangements. Major alignment errors, especially parallel offset, can be compensated.

The latest series ‘Simple-Flex’ does not require any support or compensating elements for shaft misalignment, the super-light and flexible design makes both unnecessary.