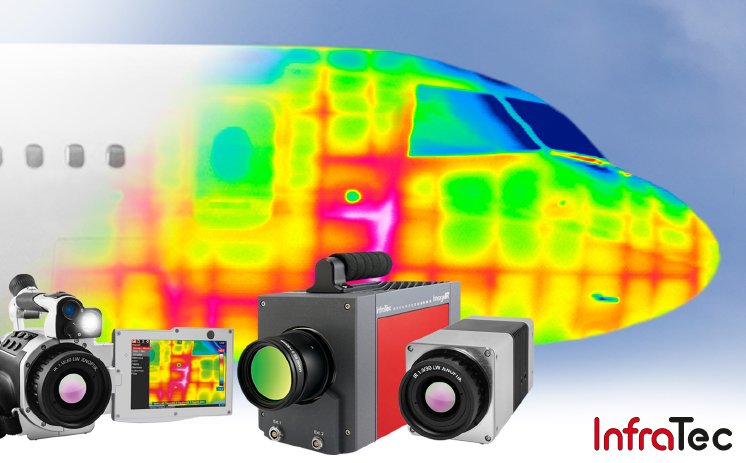

Non-destructive testing (NDT) through active and passive thermography has set new standards in this field. Both methods can be used to visualize and analyse a lot of materials for different types of errors. These methods save money due to the fact that the examined pieces remain intact, and are also efficient because thermal imagers can capture large areas. Facts that are becoming more relevant for the industry, as quality and reliability must always be matched with profitability.

Depending on the process, users can make temperature differences visible for processes that are inherent or caused by externally induced heat flows. Depending on the structure and the thermal conductivity of the analysed material, errors in deeper layers can also be precisely identified. Things like impact damage, delamination, inserts, curing or adhesive failures in frames and stringers can be accurately assessed in terms of type, size and location.

For such demanding tests, InfraTec provides two powerful solutions with the high-end camera series ImageIR® and the VarioCAM® High Definition series. The thermal imagers enable precise, high-resolution temperature measurements of CFRP panels, which are required due to the large differences in the thermo-physical properties of the fibre-reinforced composites. A specially-developed precision calibration ensures high measurement accuracy.

Both thermal imaging system series are impressive in their stand-alone versions and as components of turnkey automation solutions. In combination with efficient control and analysis, as well as customised and appropriate continuous operation excitation sources and controllers, InfraTec offers the total package. The NDT user can flexibly adapt these systems to different test conditions.