It is therefore established practice for these printed products to be inspected throughout the production process to ensure the quality of the print. Generally speaking, companies that specialise in printing and finishing leaflets are also obliged vis-à-vis their customers to document the respective results in a traceable manner. As these are very fast processes, the use of powerful image processing components is indispensable. These enable the seamless inspection of individual products and a consistently reliable process.

The long-established company Faller Packaging with seven locations across Europe, including in Germany, Poland, Denmark and Hungary, has been using automatic camera inspection for product detection for some time now and was faced with the challenge of initiating a generational change of this technology in print finishing. As a leading supplier of pharmaceutical packaging, the company offers customised products in the areas of folding cardboard boxes, self-adhesive labels and leaflets, and combines these into individual all-in-one solutions. As the tasks in the pharmaceutical industry become more complex and specific, the demands on leaflets are also increasing. The introduction of the "Readability Guideline", for example, is intended to ensure better readability. However, this leads to texts using up to 30 percent more space. Icons or images are also being used more frequently, which also increases the amount of space required. The result is a wide variety of continuously growing formats that increase the challenges in the production process of print products. An intelligent Machine Vision solution is required.

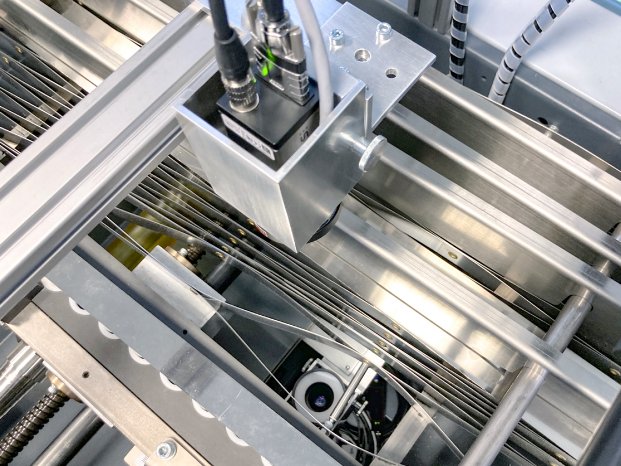

To this end, the Saxony-based company Kaiser Vision, an Machine Vision expert with 25 years of experience, has developed in close cooperation with Faller Packaging a flexible system solution for automated print image inspection. This solution combines optimally adapted software and the crucially important interaction between camera and lighting technology. Directly after printing and cutting the leaflets, an essential process step is the folding. The cut sheets are folded to the final format specified by the customer. Typically, multiple folds are made in one direction. Alternatively, a transverse fold can be made in a second process step. The key task of automatic inspection here is to check the presence and correctness of the printed image on both sides. The aim is to reliably exclude sheets printed only on one side and any mixing with other products from the next stage of the process. The detection of the printed sheets takes place directly after separation and before the actual folding, as this is the optimal point at which the products can be inspected by the camera systems. A one or two-dimensional code, e.g. a barcode or a data matrix code, is often used on leaflets to uniquely identify the processed product. The system records this and compares the content with the respective specification. Other inspection algorithms can also be used to check the presence and correctness of any printing, such as a logo or unique text.

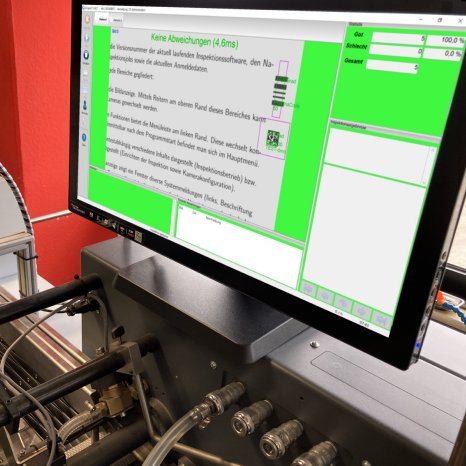

The Kaiser Vision kvInspect system allows quick and easy definition of detection areas and criteria, meaning that product changes require only a minimal amount of time. The system reliably checks every sheet passing through the folding machine. A reject gate integrated in the system can be controlled by the inspection system precisely for each individual product in order to reliably separate out defective products. If deviations from the defined parameters are detected, the process is automatically interrupted and the press is stopped. This minimises the production of non-conforming print items and the associated waste. These defects can be defined individually, enabling the end customer to make specific adjustments. A range of deviations from 0 to n can be defined for this purpose. When a product is changed, the kvInspect system automatically creates a complete and clear inspection report in the form of a PDF file. This ensures the complete documentation of the individual results. In addition to efficient and reliable algorithms for the machine image analysis, the selection of the hardware is of course decisive for the stable and reproducible function of the overall system. To achieve the optimal inspection and analysis of the individual test objects in a stable process, the focus was on the ideal interaction between camera technology, lighting and powerful algorithms. When choosing the camera, it was particularly important to combine a compact design with excellent technical properties. As the inspection processes involve very fast sequences of individual image captures and the analysis of these, it is essential to have both a short exposure time and homogeneous illumination of the image field. Due to the high demands on the required illumination system, the choice fell on one of the most powerful miniature ring lights on the market, the LUMIMAX® LSR24 (iiM AG) manufactured in Thuringia. Decades of expertise in the field of Machine Vision illumination combine maximum performance in the smallest installation space. In order to eliminate any possible blurring due to movement and to achieve minimal exposure times, thereby keeping the process stable, the lighting systems are used in flash mode. The defined light pulse and the synchronised image acquisition enable the print image to be captured perfectly. The LEDs driven over-current in flash mode provide maximum light output. The LSR24 Miniature Ring Light is thus the ideal solution to meet the requirements of installation space and illuminance. In addition to the IP67 protection rating, the LSR24 enables easy adaptation of diffusers, polarisers and other optical accessories such as darkfield attachments and dome coupling. To achieve an absolutely homogeneous illumination of the detected area, the kvInspect system uses a diffuser with perfectly coordinated transmission.

Faller Packaging has already installed the kvInspect 100% inspection system in various print finishing machines at its Binzen site and is planning to purchase additional systems. The decision-makers were impressed, among other things, by the excellent inspection performance, the comprehensive inspection reports as well as the quick installation and the compact size of the system. The production employees appreciate the intuitive and uncomplicated operation of kvInspect.