In this regard, hte has developed significant in-house testing capabilities which it has utilized in numerous research projects conducted for third-party customers in the oil and gas industry. The knowledge we have acquired over the years has directly benefited the technology solutions that we offer our customers, and which are perpetually evolving.

For more than half a century, the Fischer-Tropsch process has proven to be a brilliant technology with huge potential for converting syngas generated from gaseous or solid carbon sources such as natural gas, coal, or biomass into liquid transportable fuels and lubricants. In recent years the Fischer-Tropsch process has gained traction as an efficient solution to the daunting societal challenge of carbon recycling. Combined with pyrolysis and gasification, Fischer-Tropsch synthesis (FTS) provides an interesting way of making use of organic waste that is difficult to reuse via conventional waste recovery systems by transforming it into FT-naphtha and subsequently into valuable products.

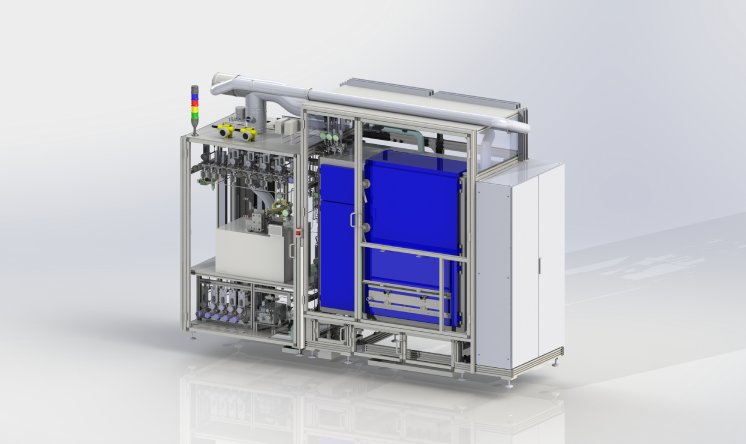

“At hte, we have observed a renewed interest in Fischer-Tropsch processes and the role they play in the CO2 value chain in the past few years. We have developed significant expertise in precisely this field to fully support our customers by providing contract research and technology solutions. It is therefore my great pleasure to announce the installation of the first Fischer-Tropsch unit for ICT in China. We really look forward to strengthening our successful collaboration with ICT in the future,” says Wolfram Stichert, CEO at hte.